- Electronic Universal Testing Machine

- Hydraulic Universal Testing Machine

- Dynamic Fatigue Testing System

-

Horizontal Tensile Testing Machine

-

Robot Automated Testing Systems

- Impact Testing Machine Series

- Compression Testing machine

- Torsion Testing Machine

- Bending Testing Machine

-

Creep and Rupture Testing Machine

-

Elastomeric Bearing Testing Machine

- Spring Testing Machine

-

Insulator Testing Machine

- Metallographic

- Hardness Tester

- Microscope

-

Plastic Pipes and Rubber Test Machine

- Melt Flow Index Tester

- HDT&VICAT Softening Point Temperature Tester

- Pendulum Impact Tester

- Hydrostatic Pressure Tester

- Plastic Pipes Ring Stiffness Tester

- Differential Scanning Calorimeter

- Moisture Meter

- Density Tester

- Ash Content Tester

- Falling Mass Impact Testing Machine

- Methylene Chloride Soak Tester

- Flame Resistance Tester

- Milling Machines

- Rubber industry testing equipment

- Environmetal Test Chamber

- Optical Spectrometer

-

Other testing equipment

- Testing equipment for masks and protective Cover

- High And Low Temperature Test Chamber

- NDT Equipment Series

- Vision Measuring Machine

- Optical Profile Projector

- Coordinate Measuring Machine

- Paper and Package Test Tester

- Textile Test tester

- Optical Test Machine

- Cupping Testing Machine

- Bolt testing equipment

- Friction and wear testing machine

- Testing machine accessories

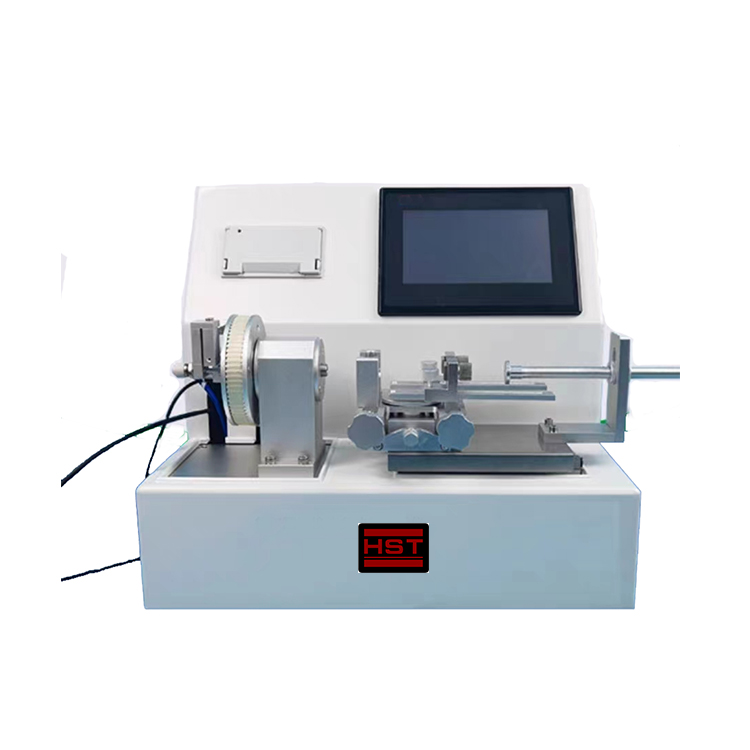

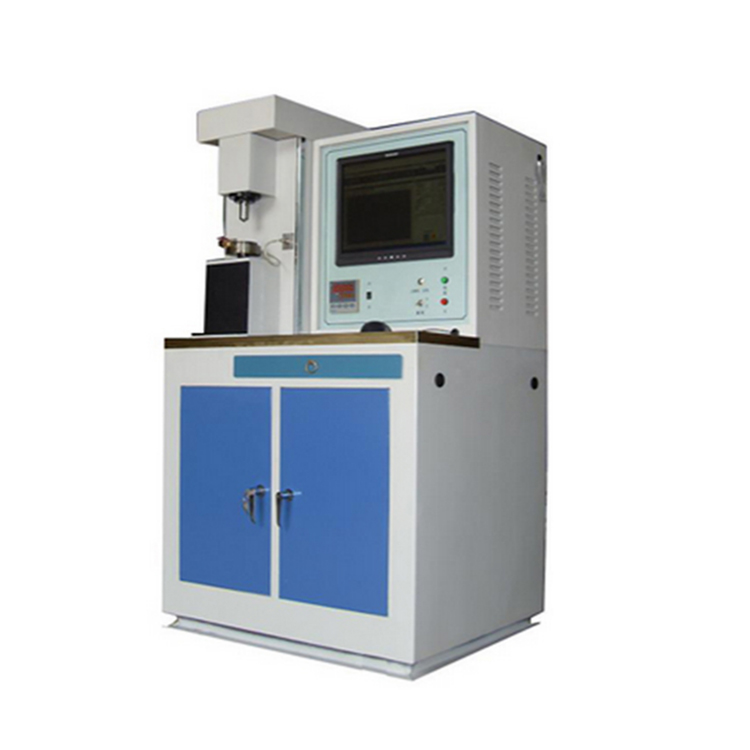

5kN/10kN/20kN/50kN Foam polymeric Material Testing Machine

It is used to test and study the mechanical properties of flexible foam polymer materials and rigid foam plastics such as indentation hardness, compressive strength, tensile force, tensile strength and other mechanical properties.

1. Test materials:

Flexible foam polymer materials (latex foam, polyurethane (PU) foam, polyurethane flexible foam, polyvinyl chloride (PVC) open-cell foam, high resilience foam (HRF), bulk foam, slow resilience foam, Experimental testing and research on mechanical properties such as crust foam (ISF), semi-rigid energy absorbing foam, ordinary soft foam, super soft foam, high load-bearing soft foam, and high resilience foam.

Rigid foam (polystyrene foam, rigid polyurethane foam, phenolic foam, amino foam, epoxy foam, thermosetting acrylic resin, rigid polyvinyl chloride foam) and other mechanical properties the study.

Furniture cushion material, vehicle seat cushion material, soft liner laminated composite material, interlayer material, filter material, sound insulation material, shockproof material, construction material, decoration material, packaging material, heat insulation material, automobile steering wheel, head Experimental testing and research on foam polymerization mechanical properties of pillows, armrests, motorcycle seats, bicycle seats, easy chair armrests and headrests, door handles, spoilers, bumpers, etc.

2. Features:

Indentation hardness index; indentation hardness characteristics (indentation force value ratio, indentation 25%, 65%, 40%); indentation hardness test.

Support plate (smooth and smooth ¢ 6x20mm porous); preload 5N; indentation (70 ± 2.5)%; unloading-loading; deformation retention.

Tensile strength, tear strength, elongation at break, relative deformation / compression deformation 10%, compression elastic modulus. Rigid foam (no flexibility, high compression hardness, deformation can be generated when the stress reaches a certain value, and it cannot be restored after stress relief; ISO stipulates that the foam is reduced to more than 10% after compression to 50% and then relieved of pressure. Styrofoam).

3.Technical Parameters

| Model | WDW-10 | WDW-10E | WDW-20 | WDW-20E | WDW-30 | WDW-30E | WDW-50 | WDW-50E |

| Max. Load(kN) | 10 | 10 | 20 | 20 | 30 | 30 | 50 | 50 |

| Load accuracy | Class 1 | Class 0.5 | Class 1 | Class 0.5 | Class 1 | Class 0.5 | Class 1 | Class 0.5 |

| Load range | 2%~100%F·S | 0.2%~100%F·S | 2%~100%F·S | 0.2%~100%F·S | 2%~100%F·S | 0.2%~100%F·S | 2%~100%F·S | 0.2%~100%F·S |

| Load resolution | 1/300000 | 1/300000 | ||||||

| Resolution of deformation | 0.04um | 0.04um | ||||||

| Accuracy of displacement | Within±0.5%of indicating load | Within±0.5%of indicating load | ||||||

| Resolution of displacement | 0.01mm | 0.01mm | ||||||

| Test speed(mm/min) | 0.05-1000 stepless arbitrary setting | 0.05-500 stepless arbitrary setting | ||||||

| Speed accuracy | within ±1% / ±0.5% of set speed | within ±1% / ±0.5% of set speed | ||||||

| E-Tensile space(mm) | 800 (can be customized) | 700 (can be customized) | ||||||

| E-Compression space(mm) | 800 (can be customized) | 700 (can be customized) | ||||||

| D-Test width(mm) | 400 (can be customized) | 500 (can be customized) | ||||||

| F-Beam travel distance(mm) | 1140 | 1050 | ||||||

| H-Workbench thickness(mm) | 30 | 58 | ||||||

| I-Base height(mm) | 210 | 435 | ||||||

| Power supply | AC220V±10%,50Hz/60Hz (can be customized) | AC220V±10%,50Hz/60Hz (can be customized) | ||||||

|

Video show |

https://youtu.be/KylRjSt60mQ | https://youtu.be/KylRjSt60mQ | ||||||