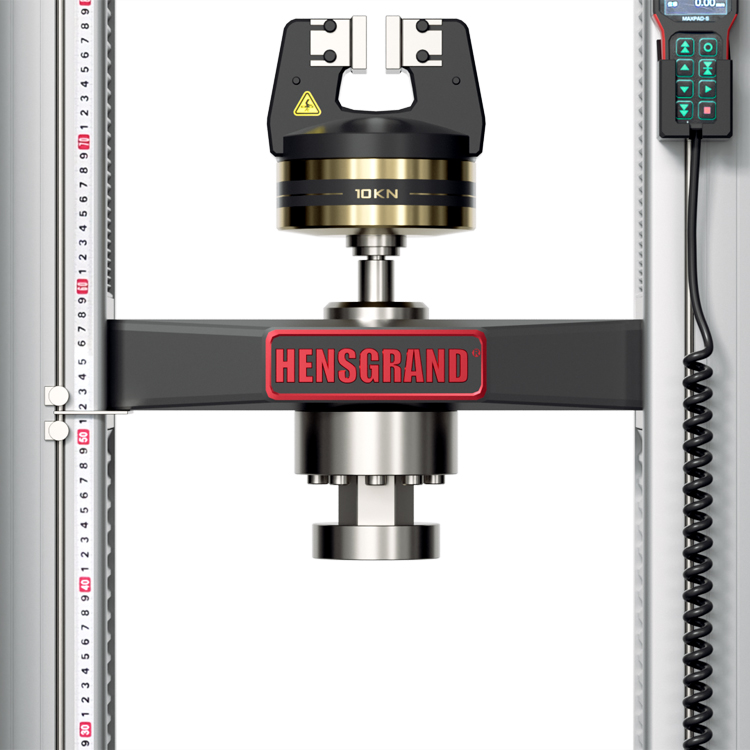

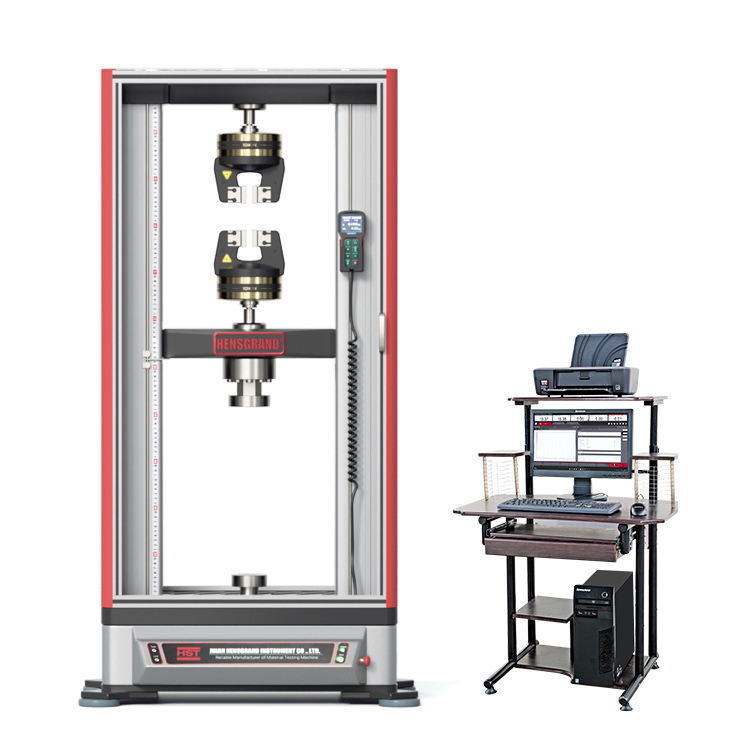

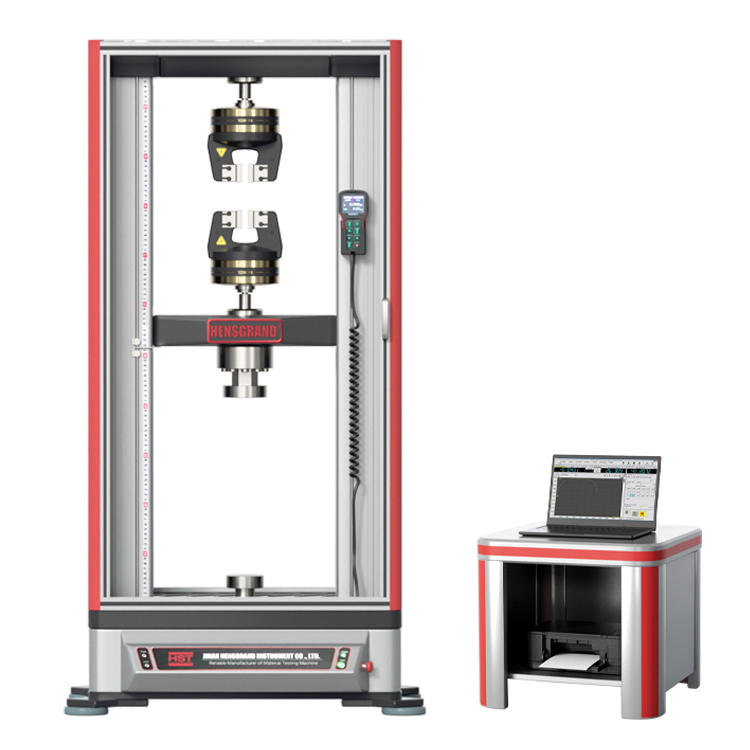

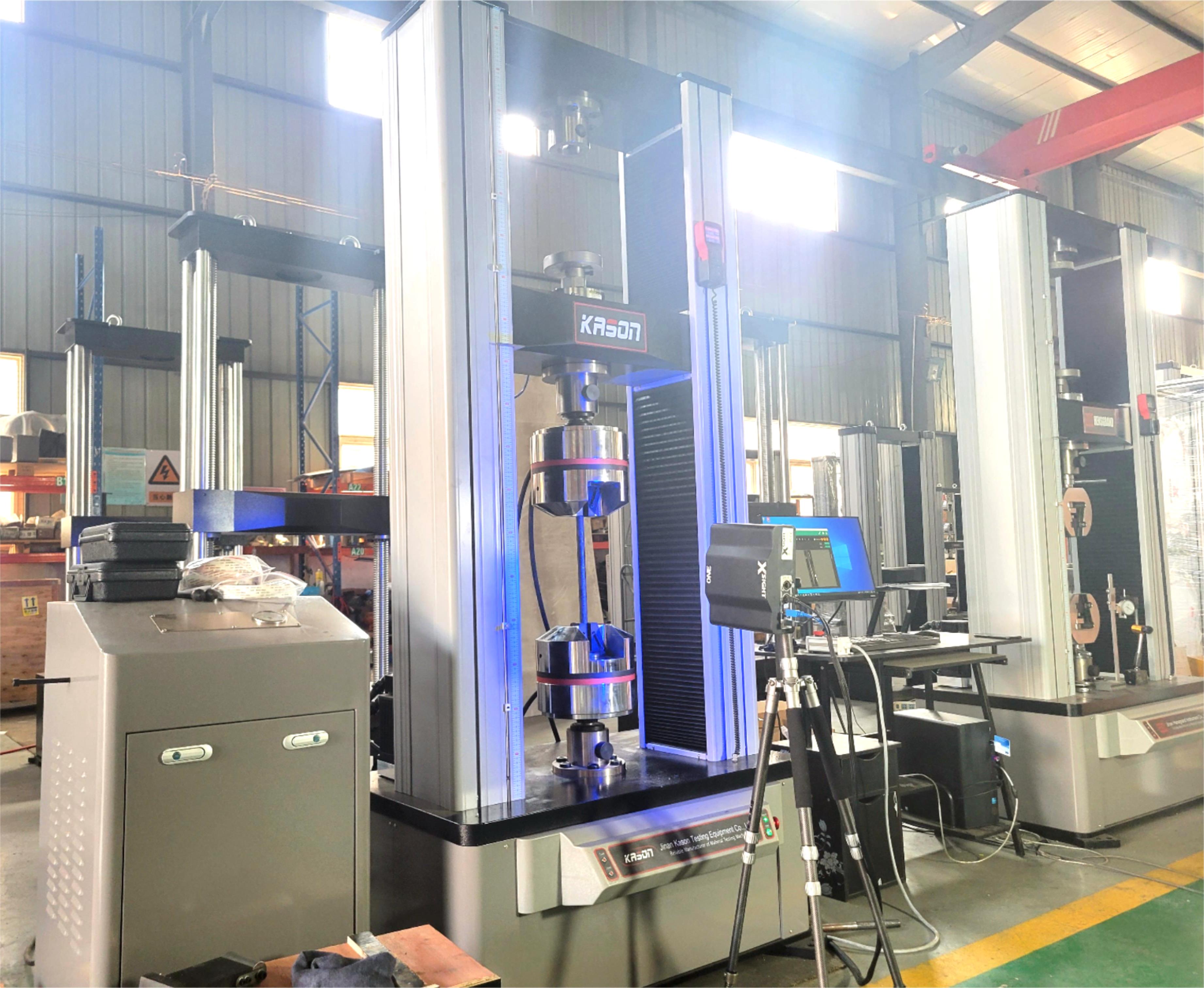

HST WDW-100E 100KN Computer control Electromechanical universal testing machine

WDW series electromechanical testing machines offer force, displacement or deformation closed loop testing in tension, compression, flexure, shear, tear and peel etc.

Standards:

ISO 7500-1, ASTM E4, EN10002-2, BS 1610, DIN 51221, ISO6892.

Request A Quote Files DownloadApplication

It is mainly for doing tension, compression, bending, shearing, etc. test of metal and non-metal materials. It can be used in all kinds of industries.

Specifications

|

Model |

HST WDW-100E |

|

Max. Load(kN) |

100 |

|

Load accuracy |

ISO 7500 Class0.5 |

|

Load range |

0.4%~100%F·S |

|

Accuracy of test load |

≤±0.5% |

|

Load resolution |

1/ 500000 |

|

Resolution of displacement(μm) |

0.04μm |

|

Test speed(mm/min) |

0.001-500 |

|

Speed accuracy |

within ±0.5% set speed |

|

Tensile space(mm) |

650 |

|

Compression space(mm) |

1000 |

|

Test width(mm) |

550 |

|

Dimension(L*W*H)(mm) |

950*660*2000 |

|

Wight(KG) |

690 |

|

Power supply |

AC220V±10%,50Hzcan be cust |