ASTM D638: tensile test for plastics

HOW TO OPTION A TENSILE STRENGTH TEST ON PLASTICS ACCORDING TO ASTM D638

The ASTM D638 standard describes the test method for determination of the tensile properties of reinforced and unreinforced plastics. It helps determine essential mechanical properties, including tensile stress, strain, tensile modulus, tensile strength, tensile strength at yield and tensile strength at break.

What Does ASTM D638 Measure?

Tensile Strength Tensile strength is the amount of force that can be applied to a plastic material before it yields (stretches irreparably) or breaks. This parameter is crucial for understanding how much stress a material can withstand before failing.

Tensile Modulus The tensile modulus indicates how much a material can deform in response to stress before yielding. The modulus is a measure of the material’s stiffness, representing its ability to resist deformation.

Elongation Elongation is the increase in the gauge length after breaking divided by the original gauge length. Greater elongation indicates greater ductility, meaning the material can plastically deform without breaking.

Poisson’s Ratio Poisson’s ratio measures the relationship between how much a material is stretched and how much it thins during the stretching process. This parameter is important for understanding the three-dimensional behavior of the material under stress.

Required Equipment

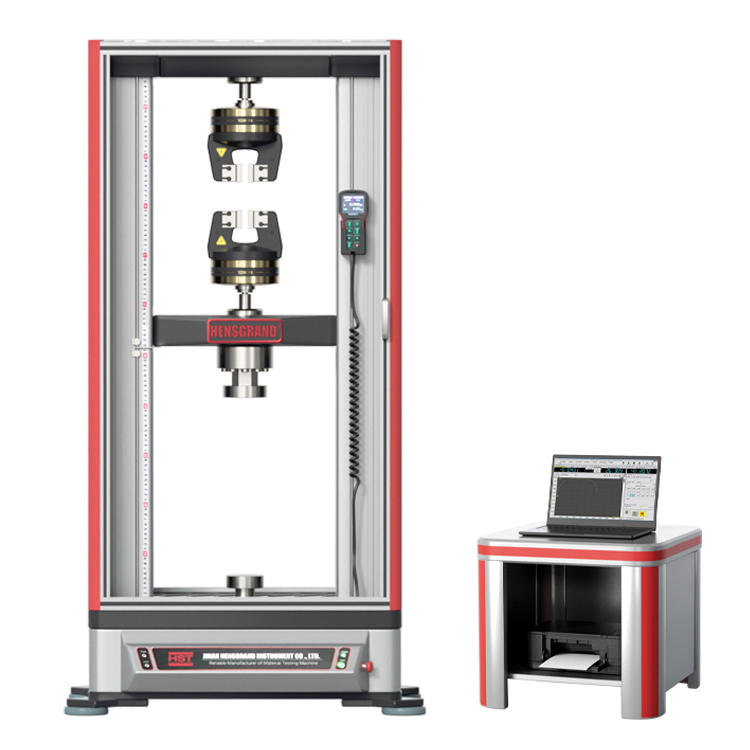

Universal Testing Machine Most ASTM D638 tests are performed on a benchtop universal testing machine. These machines are designed to apply a controlled tensile force to the samples, measuring various properties during the process.

Types of Samples

Type I Samples Type I samples, with a thickness of 3.2 mm, are the most common and are generally created through injection molding. They have a total length of 165 mm and a width of 13 mm, with a gauge length of 50 mm.

Type IV and V Samples When the material is limited, many laboratories use Type IV or V samples. Type IV samples have dimensions similar to those required for ASTM D412 Die C cutting, while Type V samples are the smallest, with a gauge length of only 0.3 inches.

“Dogbone” Shapes Flat samples are typically molded, die-cut, or machined into a “dogbone” shape to ensure that the break occurs in the center of the sample rather than in the clamping areas.

Sample Preparation

Measuring Samples All samples must be measured before testing in accordance with ASTM D5947. Most typical micrometers should be suitable for making these measurements, ensuring precision and uniformity.

Using Micrometers For the testing system to display stress measurements rather than just force measurements, operators will be asked to enter the cross-sectional area (or thickness and width) of the specimen, as stress is calculated by dividing the applied force by the cross-sectional area of the specimen.

Batch Variation Die-cut or machined samples must be measured individually, but operators using injection-molded samples need only measure a single sample from a batch sample, provided the variation in that batch sample is less than 1%.

Sample Alignment

Importance of Alignment To test correctly, the samples must be held perpendicular to the faces of the jaw and not tilted at an angle. Misalignment of the samples can cause significant variation in the results.

Sample Alignment Devices One way to prevent misalignment is to use a jaw face that is close to the same width as the sample, making it relatively easy to visually adjust the alignment.

Prevention of Compression Forces When the grips are tightened on the plastic samples in preparation for performing a test, unwanted compression forces are often applied. It is important that they are not balanced after inserting the sample, as this will cause deviation in the results.

Performing the Test

Force Application Procedure ASTM D638 is performed by applying a tensile force to a specimen and measuring various properties of it under stress. The force is applied in a controlled and uniform manner until the specimen yields (yields or breaks).

Test Speed The test is conducted at a speed between 1 and 500 mm/min, depending on the specifications of the sample and the material.

Result Analysis

Interpreting Strength Data After performing the test, the collected strength data must be interpreted to determine the tensile strength of the material.

Calculating Tensile Modulus The tensile modulus is calculated based on the deformation of the material under stress, providing a measure of its stiffness.

Evaluating Elongation and Poisson’s Ratio Elongation and Poisson’s ratio are evaluated to better understand the behavior of the material during deformation.

Practical Tips

Common Errors to Avoid Avoiding common errors such as sample misalignment or applying unwanted compression forces can significantly improve the accuracy of the results.

Tips for Accurate Results Ensure that all samples are prepared and measured correctly, and use alignment devices to maintain consistency between tests.