- HOME >> SOLUTIONS >> By Standard >> Other Standards

High-speed impact testing on dashboards

In the automotive field, safety of passengers is key and drives research and development as well as quality control procedures. Every single critical component has to be tested. In the last years, car producers have looked for new and original features for car interiors design. Beside aesthetics, everything has to be in accordance with precise technical specifications; strength, durability and safety-related properties are the main properties to test.

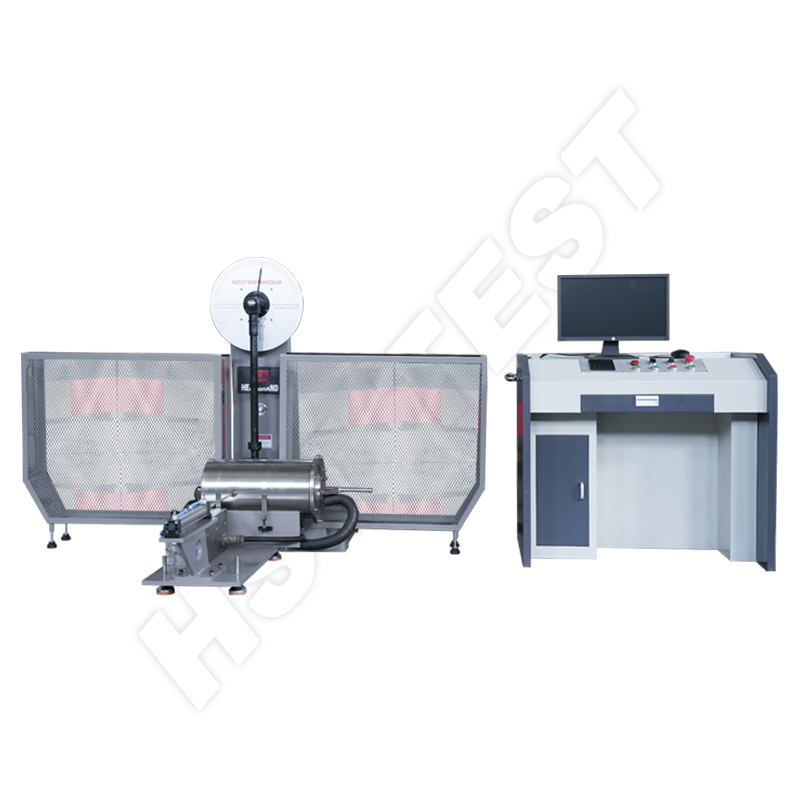

Some of the most critical parts are dashboards and surrounding items, such as steering wheel, column switch and airbags. In the event of an accident, the dashboard area will absorb a significant amount of impact energy and, when needed, airbags will deploy. Dashboards are designed to minimize and absorb shocks and therefore are constructed with different specific parts of plastics: typically a foam padding and a cover made of PVC. During the airbag deployment, PVC covers break and passengers may be injured by the projected shreds. Better and better PVC covers are being developed addressing this issue. We were asked to test a number of specimens including complete dashboards and sample plates with different characteristics. We performed high-speed impact tests at different temperatures to understand the way PVC covers break.

Some of the most critical parts are dashboards and surrounding items, such as steering wheel, column switch and airbags. In the event of an accident, the dashboard area will absorb a significant amount of impact energy and, when needed, airbags will deploy. Dashboards are designed to minimize and absorb shocks and therefore are constructed with different specific parts of plastics: typically a foam padding and a cover made of PVC. During the airbag deployment, PVC covers break and passengers may be injured by the projected shreds. Better and better PVC covers are being developed addressing this issue. We were asked to test a number of specimens including complete dashboards and sample plates with different characteristics. We performed high-speed impact tests at different temperatures to understand the way PVC covers break.