- HOME >> SOLUTIONS >> By Standard >> Other Standards

Impact Performance of Polycrystalline Diamond Cutters

When conducting exploratory drilling for oil, gas, and other natural resources, it is often necessary to penetrate tough underground rock formations using drill bits made from ultra-hard materials. Drill bits made from industrial or natural diamonds, designed for such jobs, are manufactured under extreme temperature and pressure conditions to obtain maximum hardness and durability. Both of these features are key measures of performance in this abrasive, high-speed environment.

To remain competitive, drilling companies strive to maximize the rate at which the drill head penetrates into the rock. Prematurely worn or damaged drill bits can cause a slow down in this process. To reduce costly maintenance and improve drilling efficiency, manufacturers invest heavily in materials, equipment and R&D labs. Impact testers are among the tools found in these labs for comparing drill bit material composition, cutting structure, and manufacturing processes.

Test Configuration and Procedure

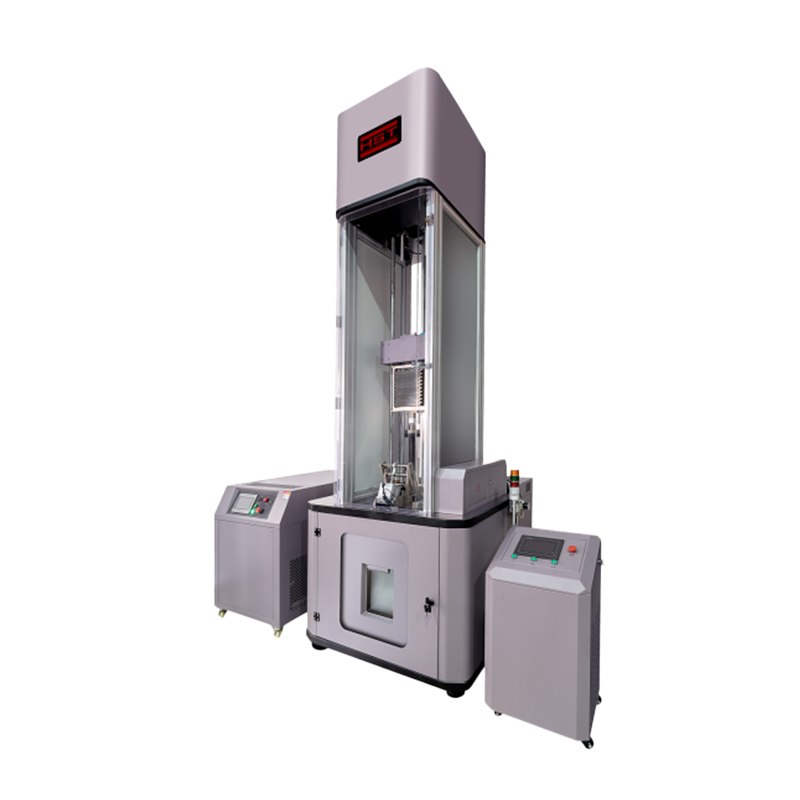

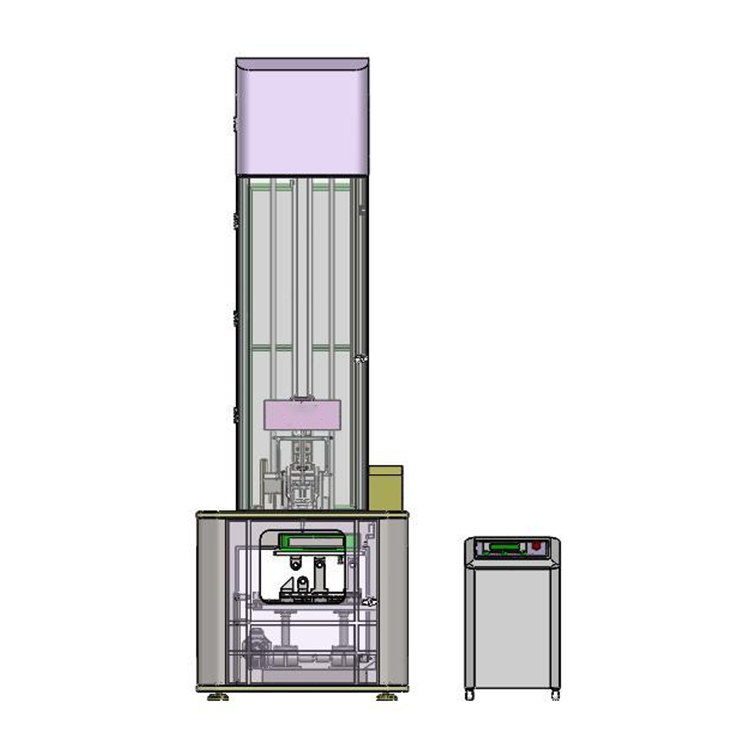

The drill bits were held at approximately 45 ° in a custom fixture developed in accordance to the industry. A HST-DIT Series Drop Weight Impact Testing machine, instrumented with a 222 kN tup, Impact software, and a custom tup insert were used to perform the testing. Due to the toughness of the specimens the tup insert was designed to allow for the insertion and removal of a carbide indenter, which had to be replaced after each impact.