- Electronic Universal Testing Machine

- Hydraulic Universal Testing Machine

- Dynamic Fatigue Testing System

-

Horizontal Tensile Testing Machine

-

Robot Automated Testing Systems

- Impact Testing Machine Series

- Compression Testing machine

- Torsion Testing Machine

- Bending Testing Machine

-

Creep and Rupture Testing Machine

-

Elastomeric Bearing Testing Machine

- Spring Testing Machine

-

Insulator Testing Machine

- Metallographic

- Hardness Tester

- Microscope

-

Plastic Pipes and Rubber Test Machine

- Melt Flow Index Tester

- HDT&VICAT Softening Point Temperature Tester

- Pendulum Impact Tester

- Hydrostatic Pressure Tester

- Plastic Pipes Ring Stiffness Tester

- Differential Scanning Calorimeter

- Moisture Meter

- Density Tester

- Ash Content Tester

- Falling Mass Impact Testing Machine

- Methylene Chloride Soak Tester

- Flame Resistance Tester

- Milling Machines

- Rubber industry testing equipment

- Environmetal Test Chamber

- Optical Spectrometer

-

Other testing equipment

- Testing equipment for masks and protective Cover

- High And Low Temperature Test Chamber

- NDT Equipment Series

- Vision Measuring Machine

- Optical Profile Projector

- Coordinate Measuring Machine

- Paper and Package Test Tester

- Textile Test tester

- Optical Test Machine

- Cupping Testing Machine

- Bolt testing equipment

- Friction and wear testing machine

- Testing machine accessories

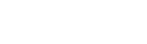

GBS-60 Digital Display Cupping Testing Machine

The cupping testing machine is used to test extend and stretch capacity of metal thin plate and band. It is the only instrument to test the metal’s plastic deformation. Also it can be used to test non-ferrous metals anisotropic character if adding impact cup mould. The machine adopts high precision raster measure instrument to test Erichsen value so it has a high testing precision. It adopts the electric control machinery onload and LCD spoke sensor so it raised the testing precision of the main test force and accuracy of controlling sample breaking.

Standards:

ISO20482: 2003 Metallic materials-Sheet and strip-Erichsen Cupping Test, GB/T4156-2007 Metallic materials-Sheet and strip-Erichsen Cupping Test.

Feature

1.Use a servo motor to load instead of hydraulic piston and cylinder;

2. Change oil pressure cylinder to load cell, more precision and reliable;

3.Auto stop when crack appears, convenient to observe the crack;

4.With peak value memory function, like max. punch load, max. deformation deep etc;

5,Turnover grips, punch and sample is easy to change;

Specification:

| Model | GBS-60 |

| Specimen thickness | 0.1-2mm |

| Max Specimen width | 100mm |

| Max Punch stroke | 60mm |

| Clamping piston stroke | 19-21mm |

| Max. punching load | 60Kn |

| Max. clamping load | 25Kn |

| Standard punch diameter | Φ20±0.05mm |

| Standard cushion mold hole diameter | Φ33±0.1mm |

| Standard press mold hole diameter | Φ27±0.05mm |

| Display resolution | 0.01mm |

| Speed | 2-100mm/min |

| Display resolution | 0.01mm |

| Display mode | LCD display |

| Display value | Clamping force, stamping force, displacement and cup drawing value, speed rate |

| Control mode | Manul adjust speed rate, Automatic adjust and record cup drawing value |

| Structure | Composite cylinder, double oil pump supply oil, grating measurement |