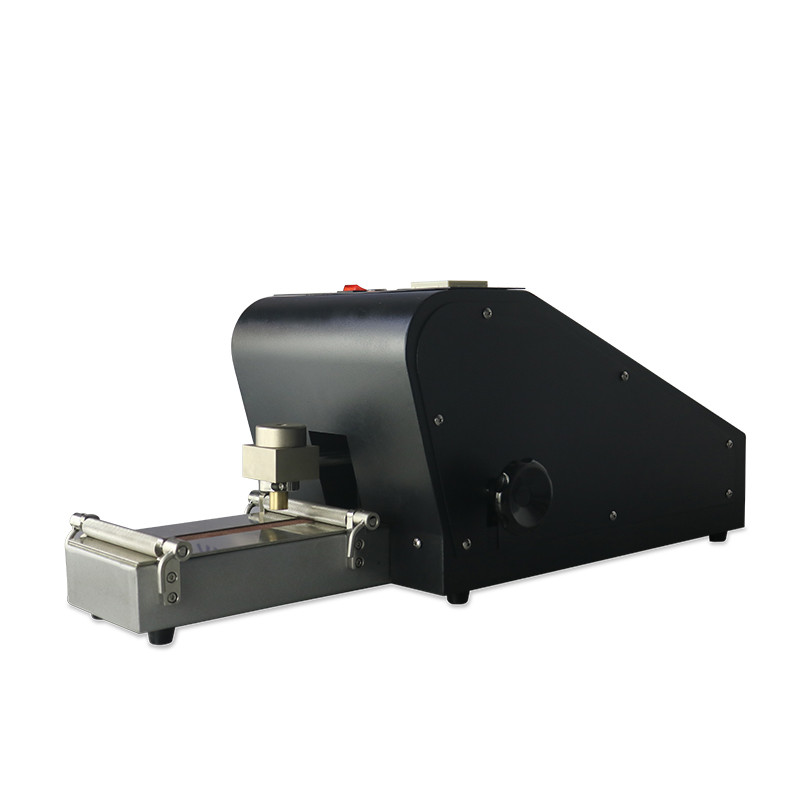

HST-YG812Q(II) Water permeability tester

Used to determine the water penetration resistance of dense fabrics such as canvas, tarpaulins, sheeting, tent fabrics, and rainproof clothing.

Standards:

HG/T 2582-2008 ,ISO 1420,AATCC 127, ISO 811-1981, JIS L1092-1998, DIN EN 20811-1992, FZ/T 01004 and other standards.

Request A Quote Files DownloadHST-YG812Q(II) Water permeability tester

Instrument Application:

Used to determine the water penetration resistance of dense fabrics such as canvas, tarpaulins, sheeting, tent fabrics, and rainproof clothing. It can also be used to test the resistance of rubber or plastic-coated fabrics to water penetration for a fixed period of time when subjected to a certain hydrostatic pressure.

Technical parameters:

1. Measurement range: 0-500kPa (50mH2O), resolution: 0.01kPa (1mmH2O)

2. Measurement accuracy: ≤±0.5% F•S

3. Number of tests: ≤99, select the delete function.

4. Test methods: Pressurization, constant pressure, water leakage

5. Constant pressure hold time: 0-99999.9s; timing accuracy: ±0.1s

6. Specimen clamping area: 100 cm²

7. Total test time range: 0 to 9999999.9, accuracy: ±0.1 s

8. Pressurization rate: (0.5 to 80) kPa/min (50 to 8000 mmH2O/min), digitally adjustable over a wide range, suitable for testing a variety of materials.

9. Maximum flow rate: ≤200 ml/min

10. Power supply: AC220V, 50 Hz, 50W

11. External size : 400 mm × 450 mm × 500 mm (L × W × H)

12. Weight: 45 kg