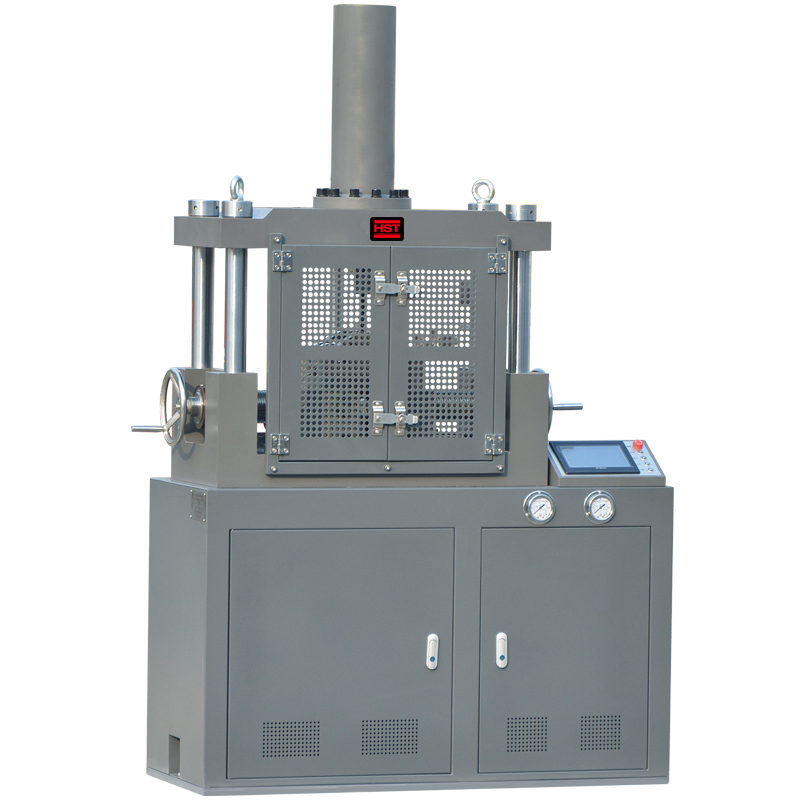

GW-H50AT Double cylinders Steel bar and plate steel bending Testing Machine

Double cylinder Steel bar and plate steel bending Testing Machine

Standards:

Request A Quote Files DownloadApplication:

This type of testing machine is designed to perform bend test on metallic materials, like rod steel, plate steel and threaded steel. It features dual-direction hydraulic loading, easy to bend specimen with diameter less than 50mm to 180° .Hand wheel drives dual-direction screw lead to adjust the support roller span. The support roller is self-lock; no need any spanner to tighten. Plug-in type mandrel is simple to change. This equipment provides speed adjustment function,and displacement and speed display function,fully complying with Clause 6.3 of ISO 7438:2005:“In case of dispute,a testing rate of(1±0,2) mm/s shall be used". It can also real-time display bending angle and facilitate for various angle tests.

Specifications:

|

Model |

HST-GW-H50AT |

|

Bending Diam Of Steel Bar(mm) |

Ф6-Ф50 |

|

Max pushing force(KN) |

500 |

|

Main Cylinder max travel(mm) |

400 |

|

Vice cylinder max travel(mm) |

200 |

|

Forward Bending Angle |

0°~180° (the angle can be set freely in the range)l |

|

Reverse Bending Angle |

20°,23°, |

|

Maximum working pressure of system

|

25 MPa |

|

Round specimen diameter(mm) |

Φ6~Φ50 |

|

Flat specimen thickness(mm) |

(6~40)x50 |

|

Mandrel diameter(mm) |

Φ18~450(can be customized) |

|

Distance between the rollers(mm) |

650 |

|

Span rollers adjustment mode |

Electric adjustment |

|

Motor Power (kw ) |

2.3 |

|

Voltage |

380V/50HZ/3 phase |