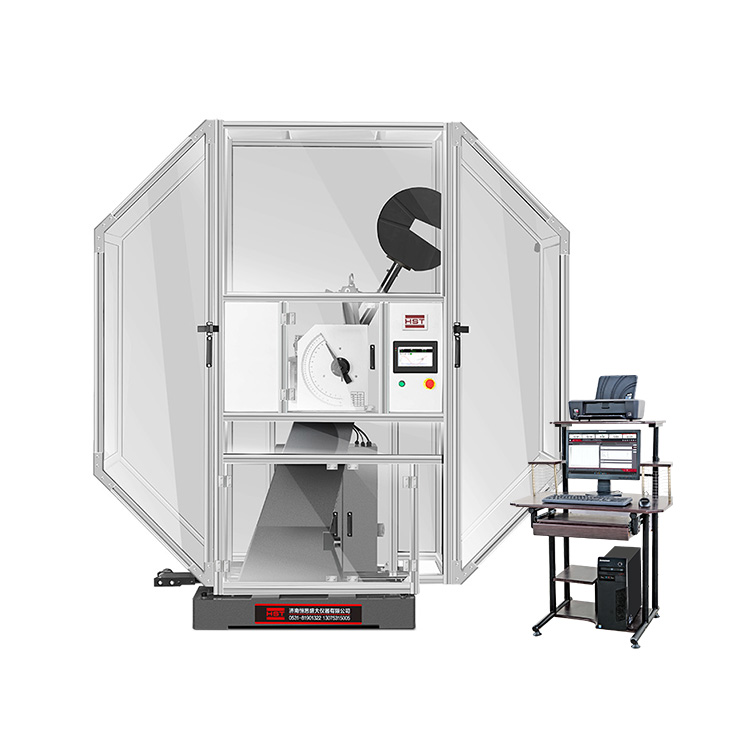

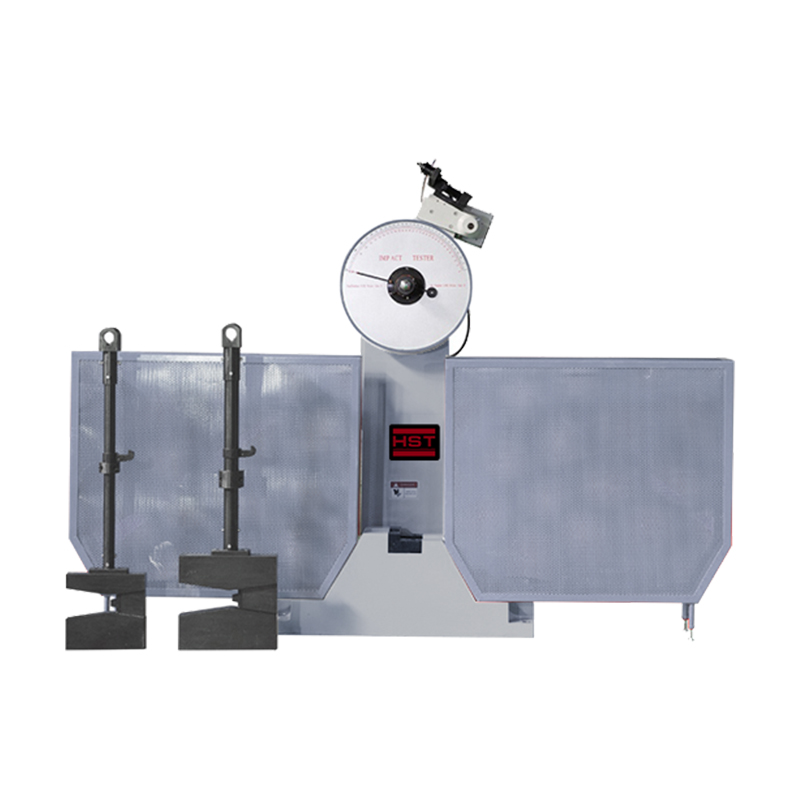

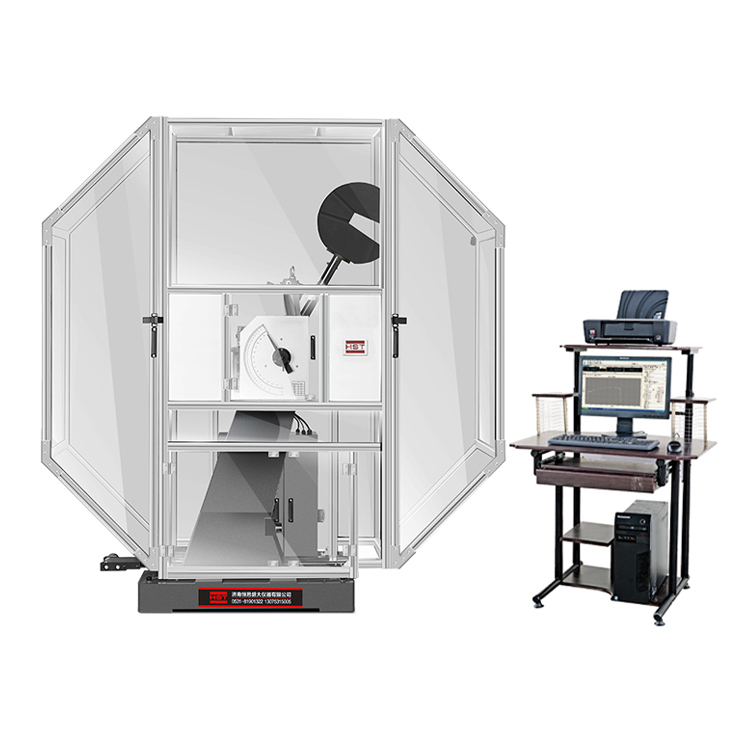

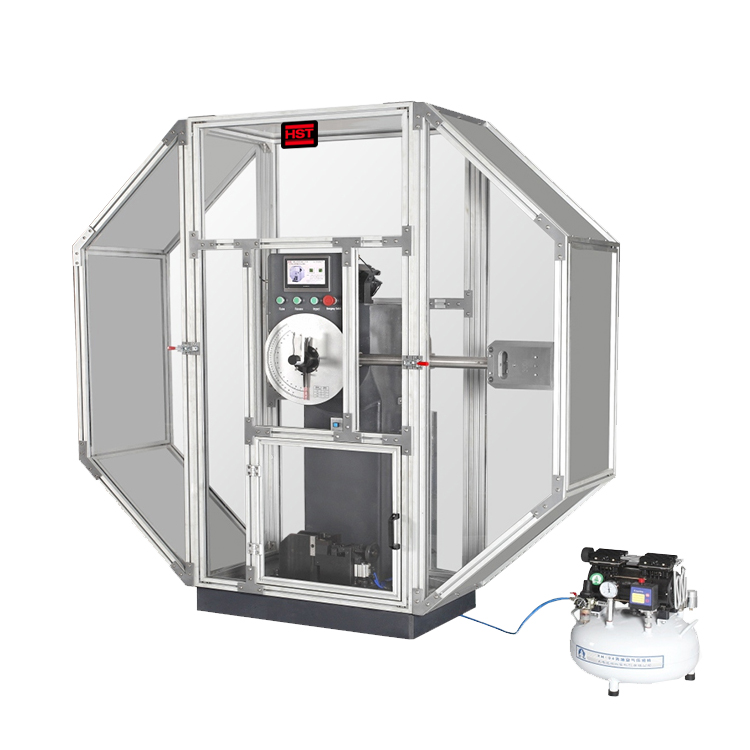

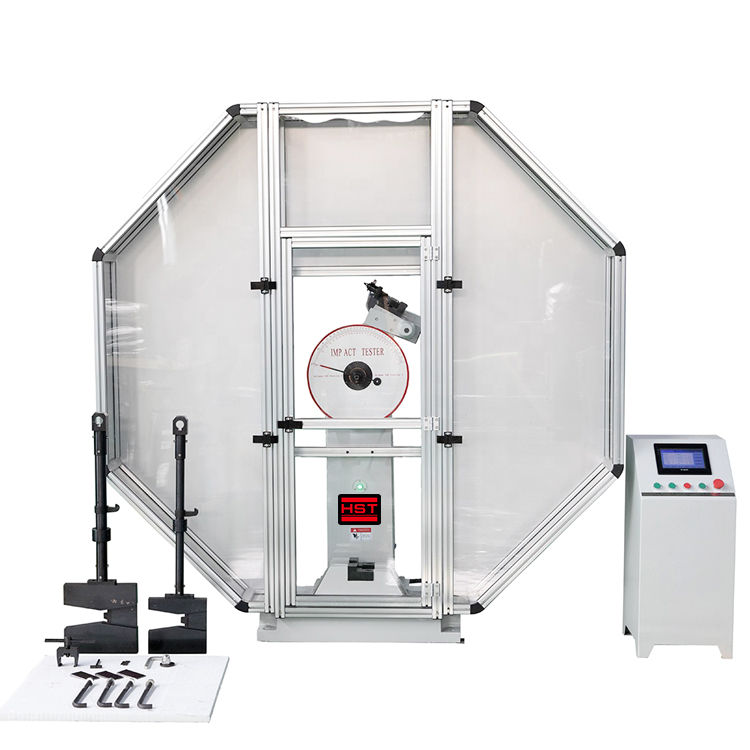

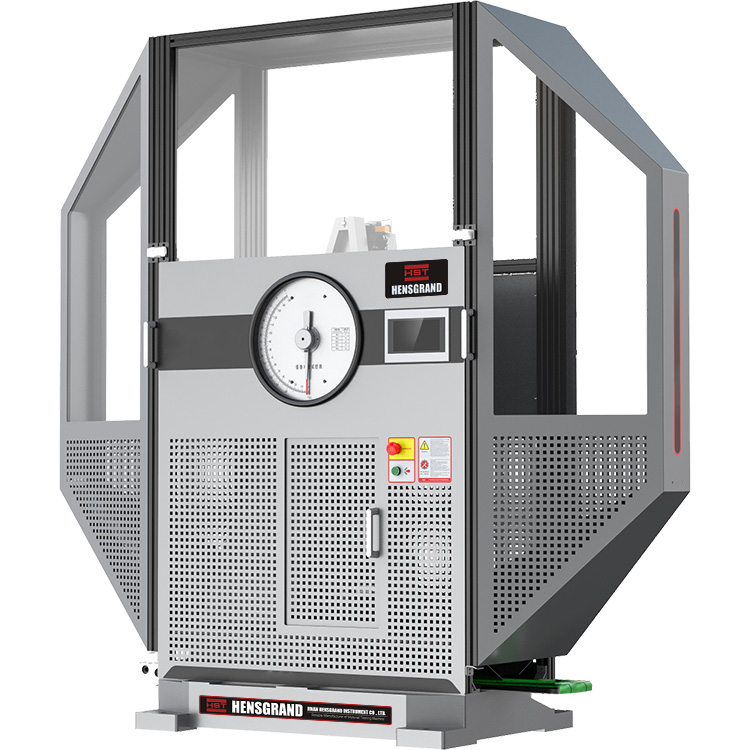

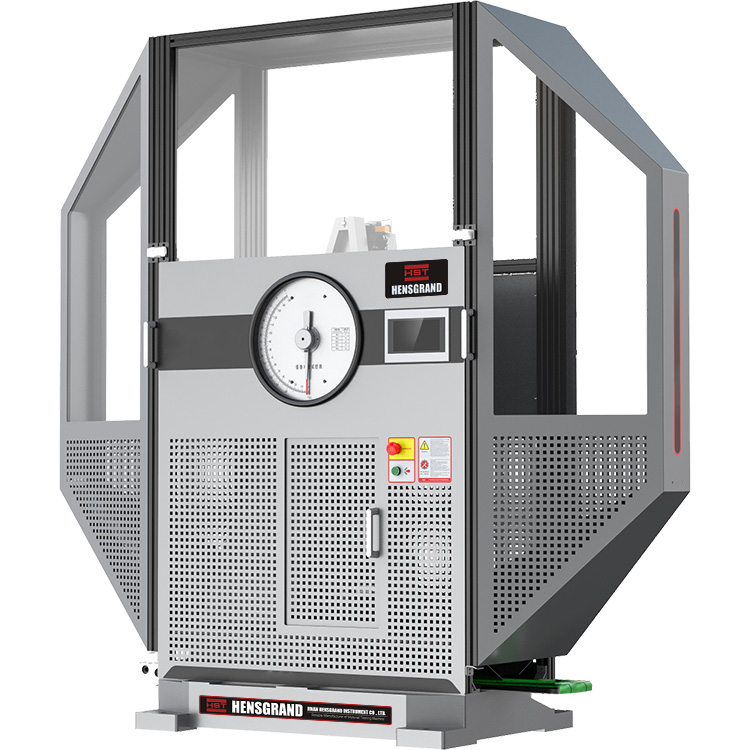

HST JBGS-450/750 Computer Control Fully Automatic High Temperature Impact Testing Machine

metal pendulum impact tester is an instrument for testing the impact resistance of metal materials under dynamic load. This model can be equipped with a fully automatic sample delivery system to impro

Standards:

Request A Quote Files Download

HST JBGS-450/750 Computer Control Fully Automatic High Temperature impact testing machine

Application:

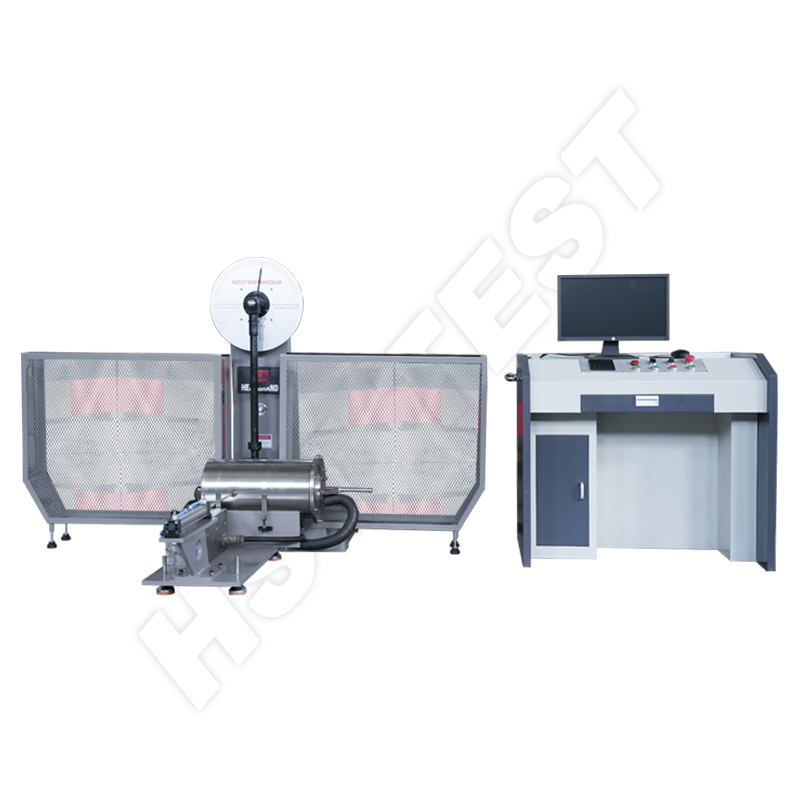

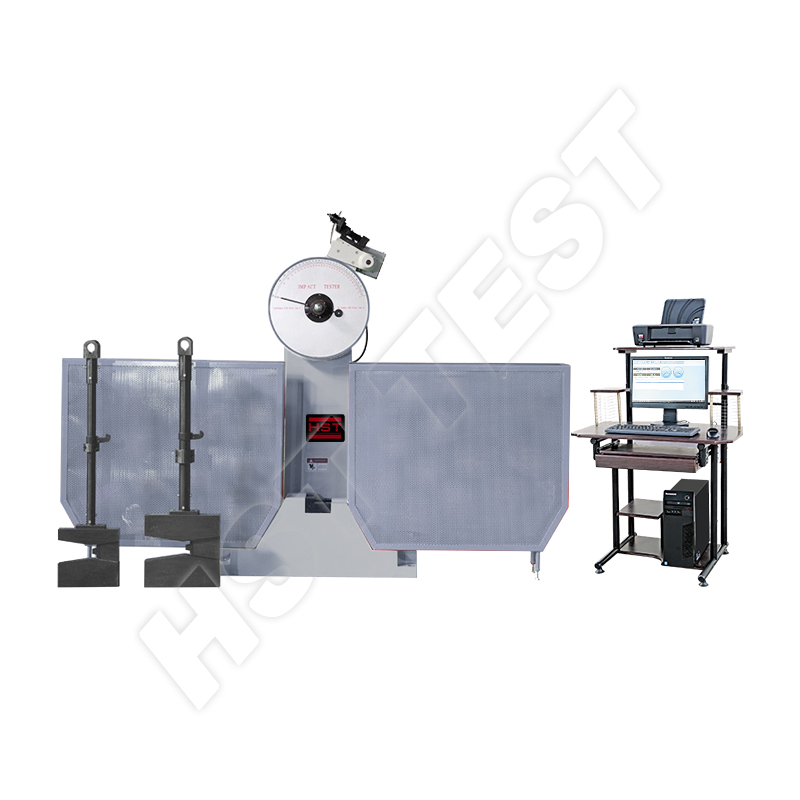

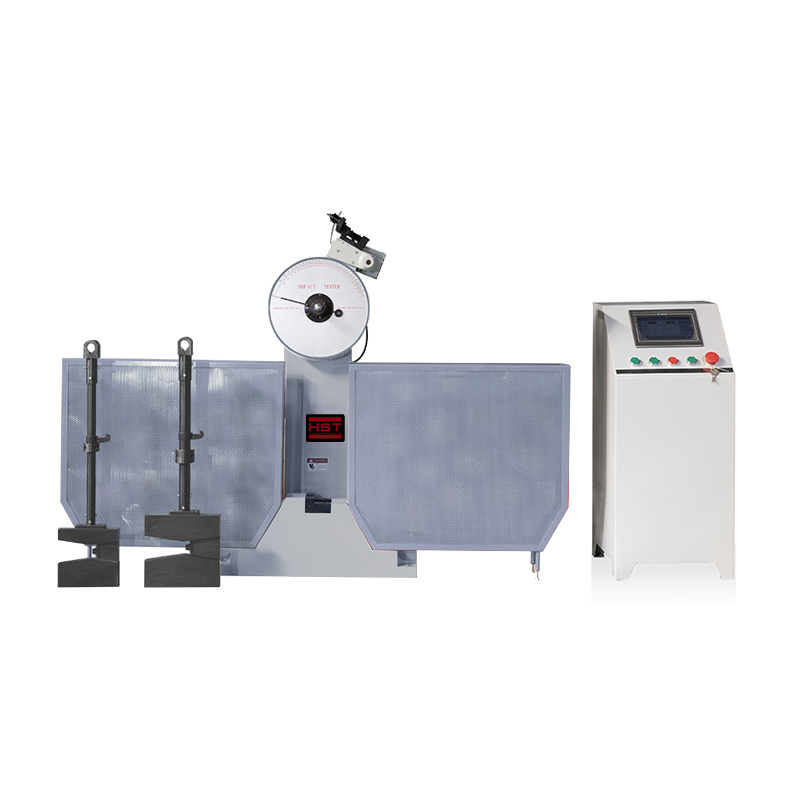

metal pendulum impact tester is an instrument for testing the impact resistance of metal materials under dynamic load. This model can be equipped with a fully automatic sample delivery system to improve test efficiency and reduce the labor intensity of test personnel.

Standards

GB/T 229 "Metallic materials - Charpy Pendulum Impact Test method"

GB/T 3808 "Inspection of pendulum impact test machine"

JJG 145 "Pendulum impact test machine"

ASTM E23 "Standard Test Methods for Notched Bar Impact Testing of Metallic Materials"

ISO 148 "Metallic materials - Charpy pendulum impact test"

Note: The referenced standards are the latest standards in effect at the date of publication.

Specifications

|

MODEL |

HST JBGS-300-900 |

HST JBGS-450-900 |

HST JBGS-600-900 |

HST JBS-750-900 |

|

Max. impact energy(J) |

300 |

450 |

600 |

750 |

|

Pendulum torque(N·m)

|

M=80.3848 |

M=160.7695 |

M=241.1543 |

M=321.5390 |

|

Raised angle(mm) |

150°±1° |

|||

|

Angular resolution (°) |

0.025 |

|||

|

Distance from the axis of support to the center of percussion(mm) |

750 |

|||

|

Angular resolution (°) |

0.025 |

|||

|

Air impact absorption |

≤0.4% |

|||

|

Standard span(mm) |

40 |

|||

|

Round angle of the jaw |

R (1.0~1.5)mm (1mm is special ordered.) |

|||

|

Angle of Taper of Supports |

11°±1° |

|||

|

Angle of Striking Tip |

30°±1° |

|||

|

Thickness of Striking(mm) |

16 |

|||

|

Round corner of support jaw |

R (1.0~1.5)mm (1mm is special ordered.) |

|||

|

Blade curvature radius |

R (2.0~2.5)mm (8mm is special ordered.) |

|||

|

Standard specimen dimension(mm) |

55x10x10 , 55x10x7.5 , 55x10x5 |

|||

|

High temperature automatic sample feeding device |

300℃~900℃ |

|||

|

Power supply |

3phs, 380V/220V±10%, VAC50Hz or specified |

|||

|

Dimensions (mm) |

2150x2150x860 |

|||