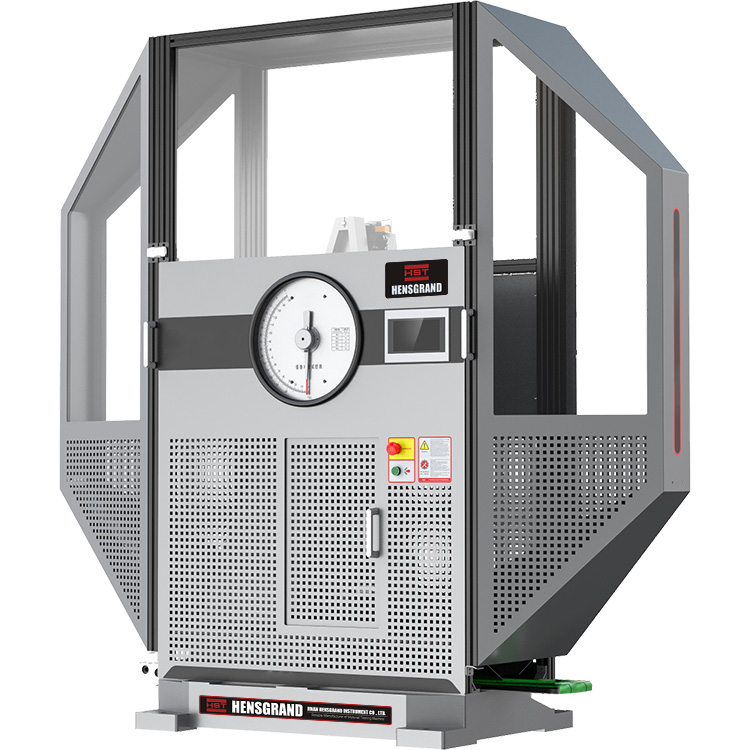

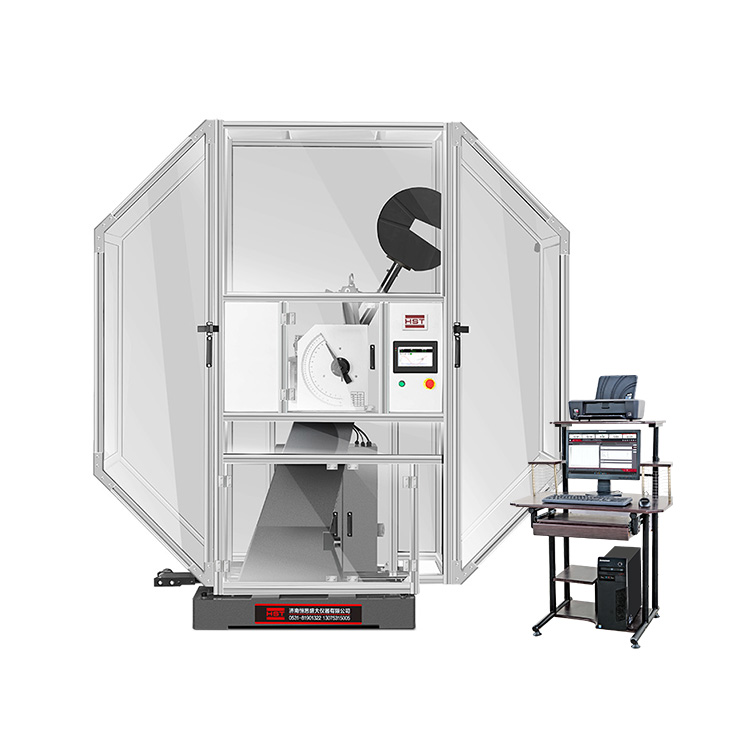

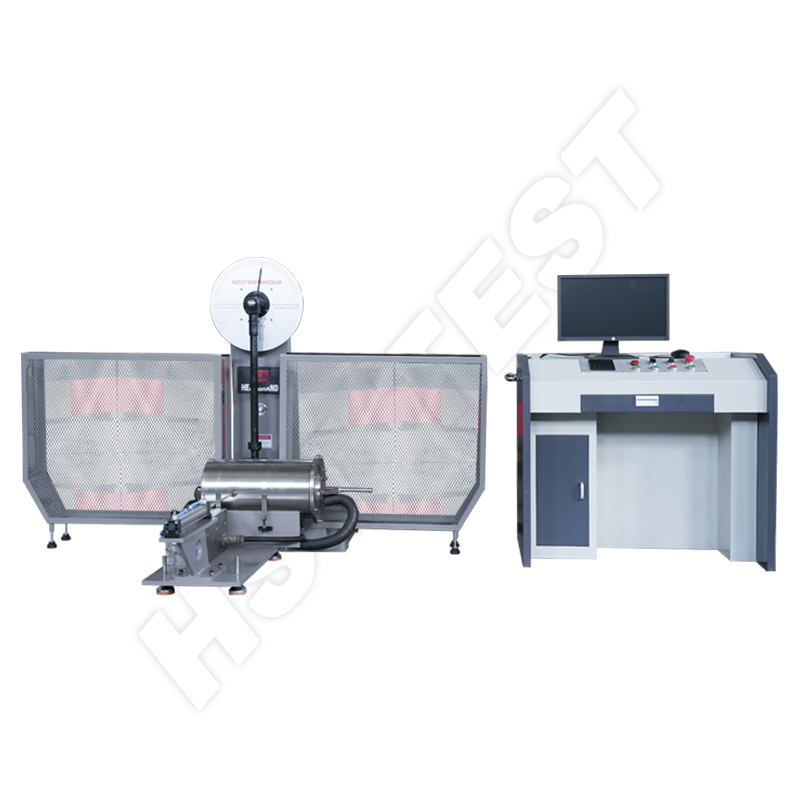

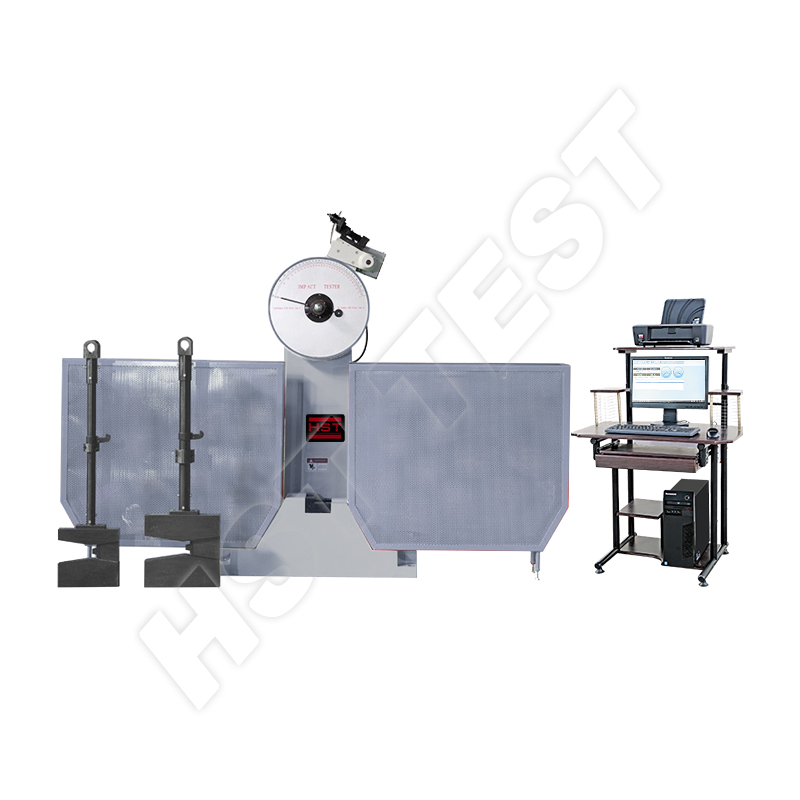

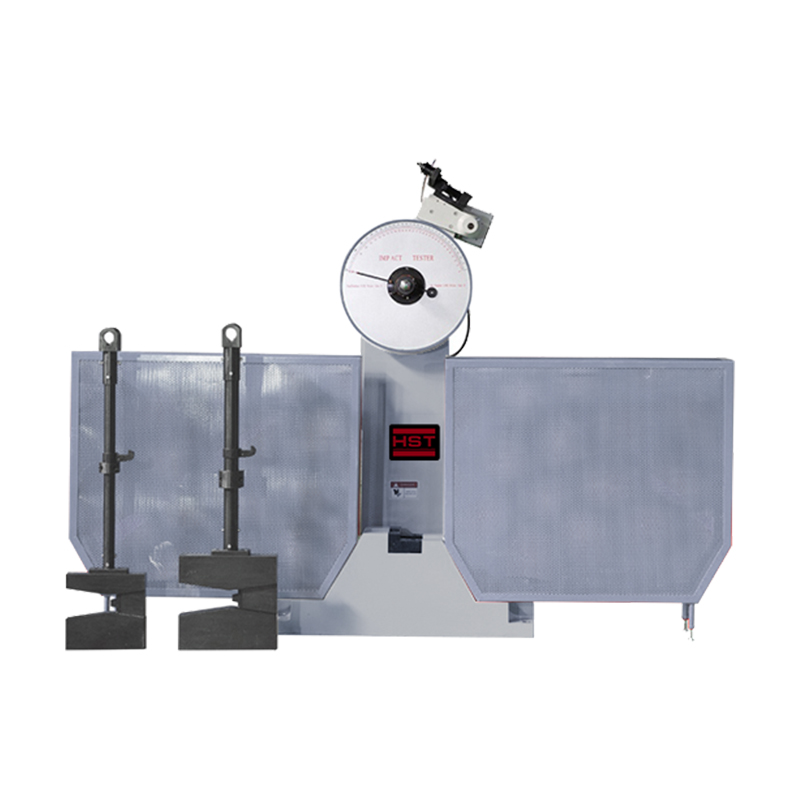

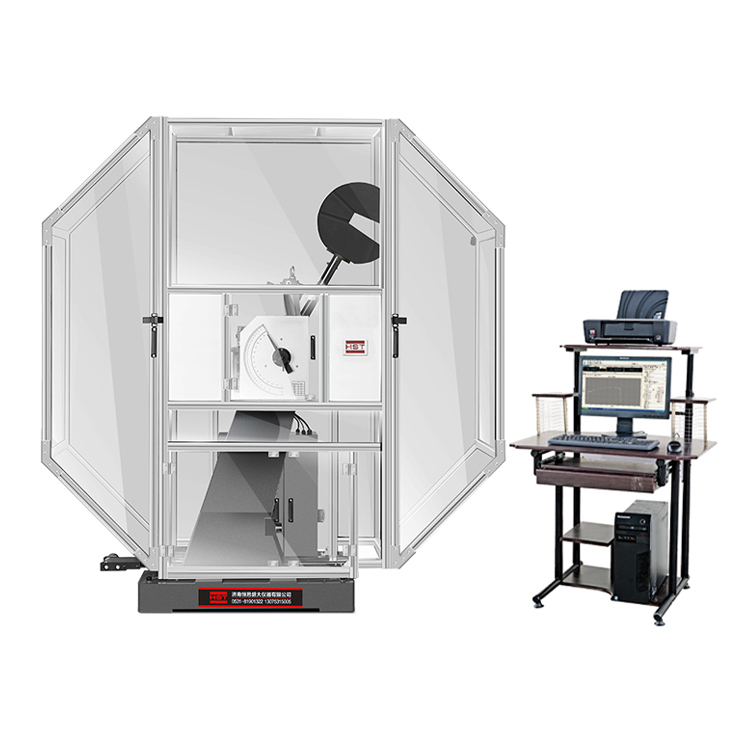

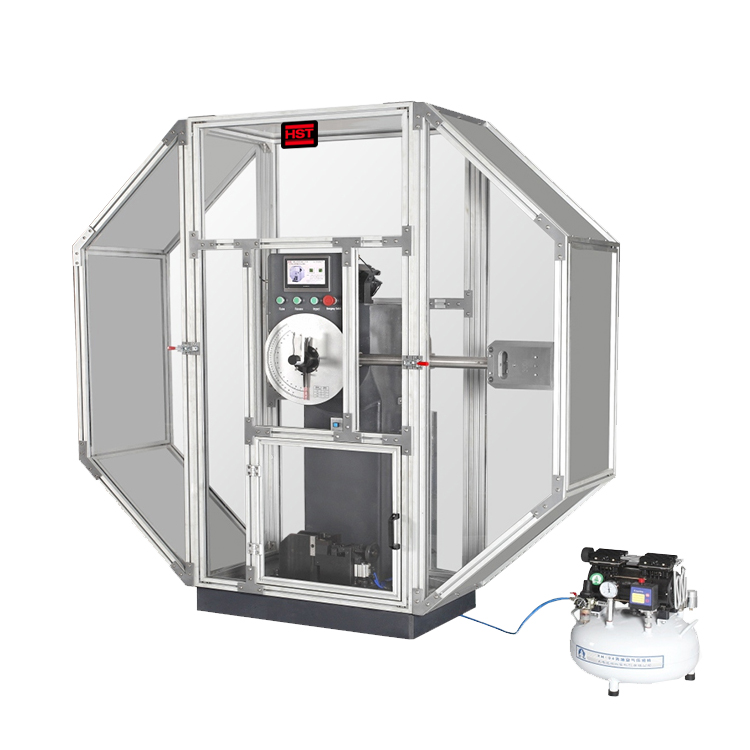

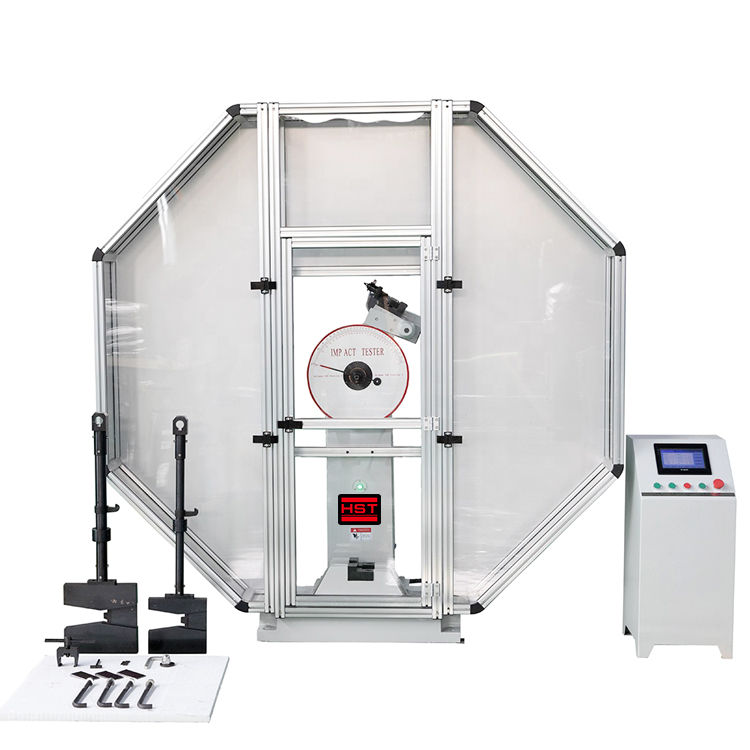

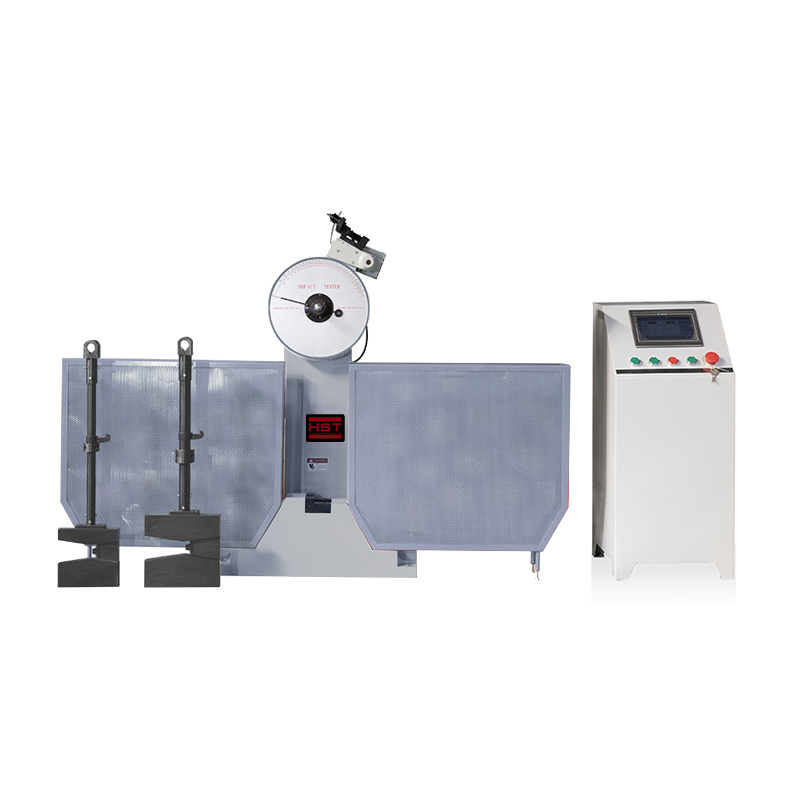

HST-JBS300B/500B Digital Display Pendulum Impact Testing Machine(300J/500J)

JBS-B Series Touchscreen Digital Display Semi-automatic Impact Testing Machine is mainly used to determine the anti-impact capability of ferrous metal materials with high toughness.

Standards:

ISO148, EN10045, ASTM E23, GB/T3808-2002 ,GB/T229-2007.

Request A Quote Files DownloadHST-JBS300B/500B Digital Display Pendulum Impact Testing Machine(300J/500J)

Application:

JBS-B Series Touchscreen Digital Display Semi-automatic impact testing machine is mainly used to determine the anti-impact capability of ferrous metal materials with high toughness, especially for steel and iron and their alloy, under dynamic load.This series tester is operated semi-automatically, the pendulum of the machine can be raised or released automatically.

Be applicable for continuing testing in different kinds of laboratories and other metallurgy industrial manufactories.

Technical Specifications:

| Model | JBS-300B | JBS-500B |

| Impact Energy | 150 J / 300 J | 250 J / 500 J |

| Control Methods | Single Chip Control | |

| Display Way | Dial Display and Digital Display | |

| The Distance Between The Pendulum Shaft And Impact Point | 750 mm | 800 mm |

| Minimum Reading Value | 1 J | 2 J |

| Impact Speed | 5.2 m/s | 5.4 m/s |

| Pre-rising Angle Of The Pendulum | 150° | |

| Specimen Bearer Span | 40+0.2 mm | |

| Round Angle Of The Jaw | R 1.0~1.5 mm | |

| Round Angle Of Impact Edge | R 2.0~2.5 mm(Optional: R8±0.05 mm) | |

| Angle Accuracy | 0.1° | |

| Pendulum Torque | M=160.7695N.m 80.3848N.m | |

| Standard Specimen Dimension | 10 mm * 10(7.5 or 5) mm * 55 mm | |

| Impact Pendulum Configuration | 150 J, 1 PC; 300 J, 1 PC | 250 J, 1 PC; 500 J, 1 PC |

| Power Supply | 3phs, 380V, 50Hz | |

| Dimensions | 2124mm * 600mm * 1340mm | |

| Net Weight | 480 KG | 610 KG |