- Electronic Universal Testing Machine

- Hydraulic Universal Testing Machine

-

Horizontal Tensile Testing Machine

- Steel Wire Testing Machine

- Dynamic Fatigue Testing System

-

Robot Automated Testing Systems

- Impact Testing Machine Series

- Compression Testing machine

- Torsion Testing Machine

- Bending Testing Machine

-

Creep and Rupture Testing Machine

-

Erichsen Cupping Testing Machine

-

Elastomeric Bearing Testing Machine

- Spring Testing Machine

-

Insulator Testing Machine

- Metallographic

- Hardness Tester

- Microscope

-

Plastic Pipes and Rubber Test Machine

- Melt Flow Index Tester

- HDT&VICAT Softening Point Temperature Tester

- Pendulum Impact Tester

- Hydrostatic Pressure Tester

- Plastic Pipes Ring Stiffness Tester

- Differential Scanning Calorimeter

- Moisture Meter

- Density Tester

- Ash Content Tester

- Falling Mass Impact Testing Machine

- Methylene Chloride Soak Tester

- Flame Resistance Tester

- Milling Machines

- Rubber industry testing equipment

- Environmetal Test Chamber

- Intellectual_Product

- Optical Spectrometer

-

Other testing equipment

- Testing equipment for masks and protective Cover

- High And Low Temperature Test Chamber

- NDT Equipment Series

- Vision Measuring Machine

- Optical Profile Projector

- Coordinate Measuring Machine

- Paper and Package Test Tester

- Textile Test tester

- Optical Test Machine

- Bolt testing equipment

- Friction and wear testing machine

- Voltage Breakdown Tester

- Torque rheometer

- Capillary rheometer

- Plastic Friction and Wear Testing Machine

- Testing machine accessories

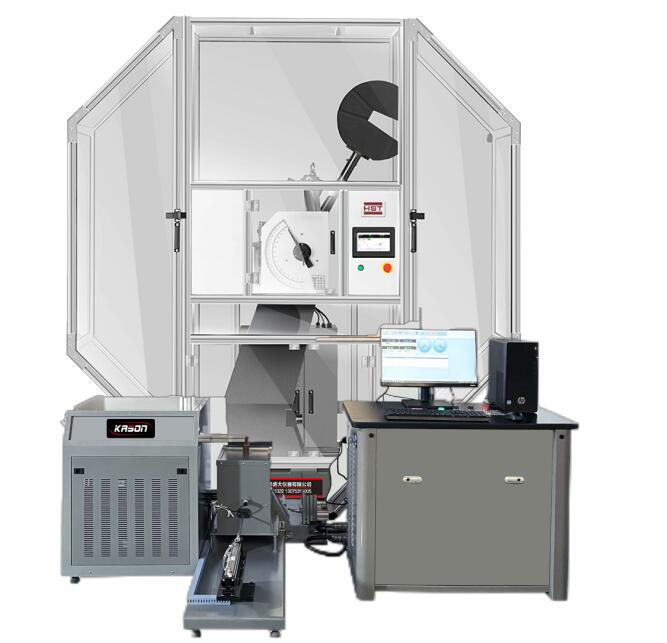

HST JBDW-300D/500D-196 Computer Low-temperature Automatic Charpy Impact Testing Machine(-196°C)

Application:

Full Automatic Impact Testing Machine was widely used in mechanical metallurgy, aerospace engineering, vessel building, academy and institute, and nuclear power engineering fields which has high requirement on temperature testing with high efficiency.

Standards:

ISO 148-1 -Metallic materials - CHARPY pendulum impact test.

JIS Z 2242 -Method for CHARPY pendulum impact test of metallic materials.

EN 10045-1 -Metallic materials-CHARPY impact test.

ASTM E23 (CHARPY) -Standard test method for notched bar impact testing of metallic materials.

GOST 9454-78 -Impact bending test method at low, room and high temperatures

Specifications

|

MODEL |

HST JBDW-300D-196

|

HST JBDW-500D-96

|

|

Impact energy (J) |

150,300 |

250,500 |

|

Value of every grid (J) |

0~300(2J), 0~150(1J) |

0~500(5J), 0~250(2.5J) |

|

Moment of pendulum(N·m) |

0~300J(160.7695N·m), 0~150J(80.3848N·m) |

0~500J(267.9492N.m), 0~250J(133.9746) |

|

Impact velocity (m/s) |

5.2 5.24 |

5.4 |

|

Distance between pendulum center and sample center (mm) |

750 |

800 |

|

Raised angle |

150º |

|

|

Standard span (mm) |

40+0.2 |

|

|

Round angle of jaws (mm) |

R1-1.5((1mm is special order) ) |

|

|

Round angle of striking edge (mm) |

R2-2.5 or R8±0.05(8mm is special order)

|

|

|

Specimen holder support surface angle

|

11°

|

|

|

The impact of the blade angle

|

30°

|

|

|

The impact blade thickness (mm)

|

16

|

|

|

Size of specimen (mm) |

55x10x10 , 55x10x7.5 , 55x10x5 |

|

|

Cooling way |

Liquid nitrogen |

|

|

Capacity of sample box |

10 |

|

|

Range of low temperature |

-196°C |

|

|

Speed of sending specimen |

≤2S |

|

|

Power supply |

3phs, 380V/220V±10%, 50Hz or specified |

|

|

Dimensions (mm) |

2124 x 600 x 1340

|

2144 x 736 x 1390 |

|

Gross weight(KG) |

550 |

750 |