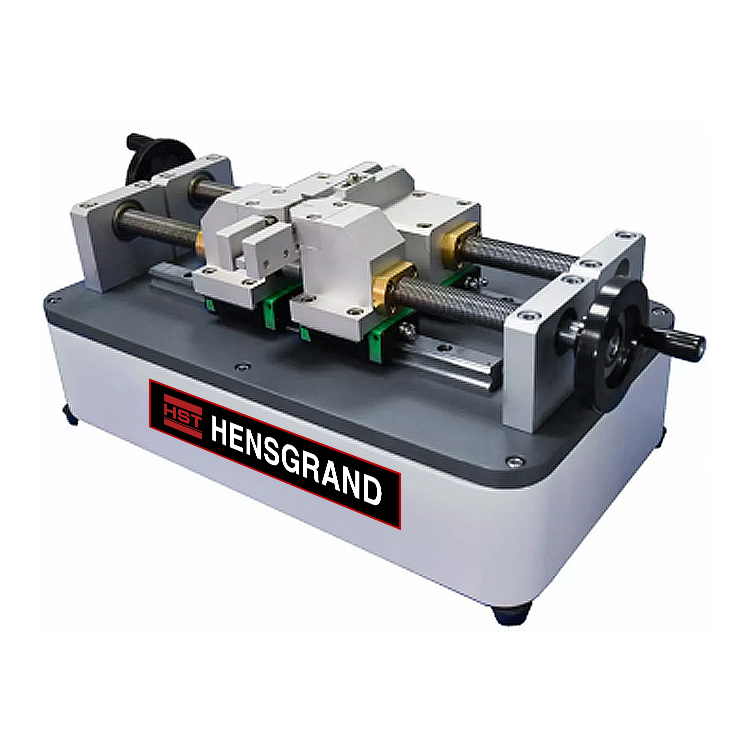

HST-KBANM II Electric notching machine

Electric notching machine is used to make notched specimens for cantilever beam and simply supported beam impact tests.

Standards:

ISO179-2000,ISO180-2000

Request A Quote Files DownloadHST-KBANM II Electric notching machine

Overview:

The electric notching machine is used to make notched specimens for cantilever beam and simply supported beam impact tests. It can be used by scientific research institutions, colleges and universities, non-metallic material manufacturers and related quality inspection agencies to make notched specimens. It is a sample making equipment with a simple structure, easy operation, and the ability to mill one or more specimens at a time with high precision.

Standards:

|

Standard number |

Standard Name |

|

ISO179-2000 |

Determination of the impact strength of plastics using a simple supported beam. |

|

ISO180-2000 |

Determination of Izod impact strength of plastics. |

|

GB/T1043-2008 |

Determination of impact properties of plastic simply supported beams |

|

GB/T1843-2008 |

Determination of Izod impact strength of plastics |

|

GB/T18743.1-2022 |

Thermoplastic pipes - Determination of simply supported beam impact strength (single notch specimen preparation) |

Technical parameters

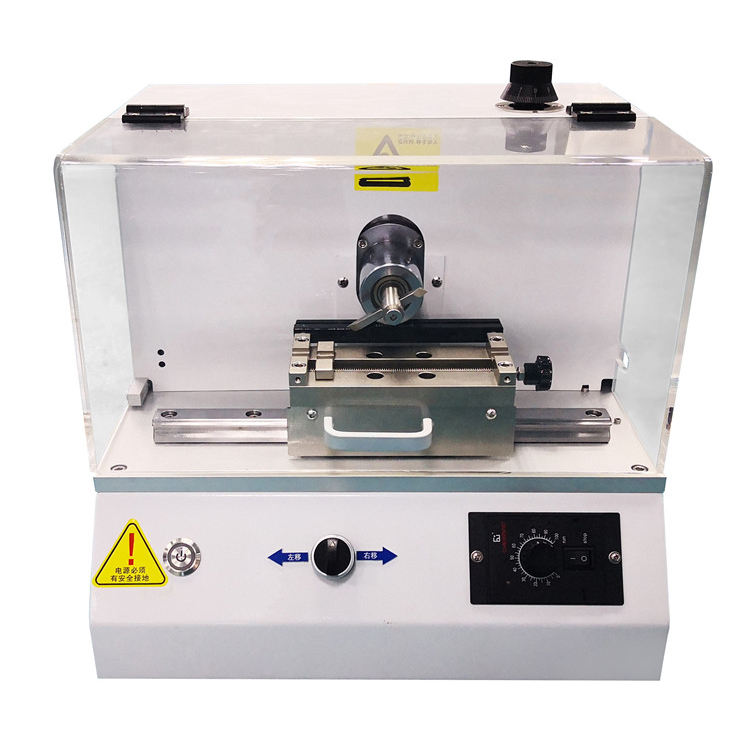

Ø Rotating motor speed: 240r/min;

Ø Tool travel: 20mm;

Ø Processing notch depth: 0~2.5mm adjustable;

Ø Workbench stroke: >90mm;

Ø Number of samples clamped at a time: 20;

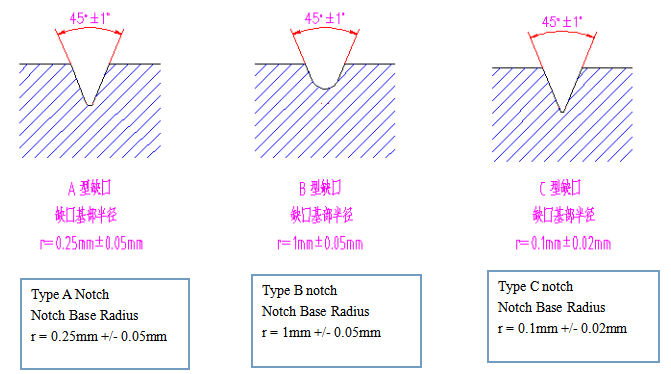

Ø Tool type parameters:Type A tool: 45°±1° r=0.25±0.05(mm);

Type B tool 45°±1° r=1.0±0.05(mm);

Type C tool 45°±1° r=0.1±0.02(mm);

Note: Users can choose any one of the above tool types according to actual needs.

Ø Power supply: AC220V±15%, single-phase three-wire.

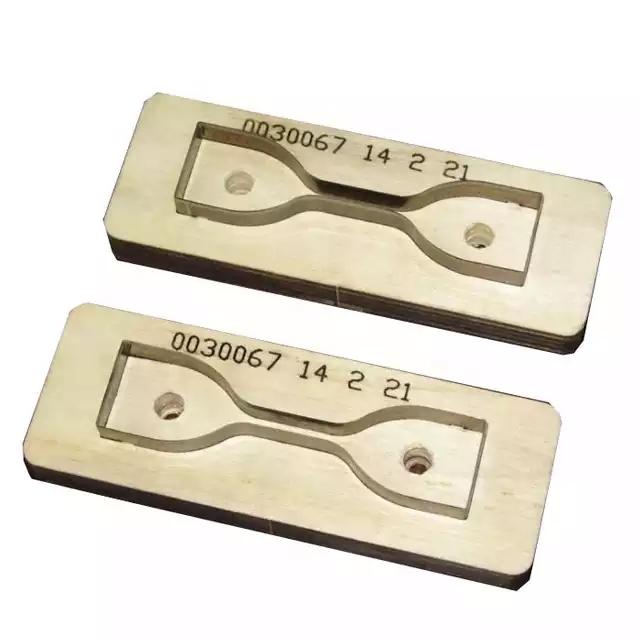

Specimen notch type