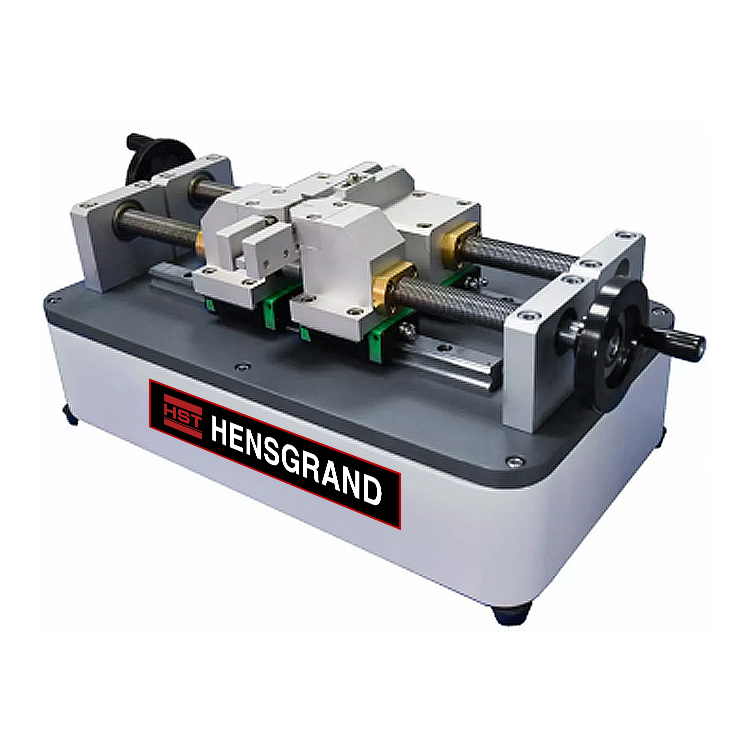

HST-LC1100 110T Tensile Test Punch Press

This equipment is an electro-hydraulic driven punch press for preparing specimens for tensile testing and other tests on sheet materials.

Standards:

Meets the latest GB/T228-2010, GB/T2975-1998, GB/T 2975-1998, GB/T Complies with standards such as 15825.5-2008, EN, DIN, and ASTM;

Request A Quote Files DownloadHST-LC1100 110T Tensile Test Punch Press

Application:

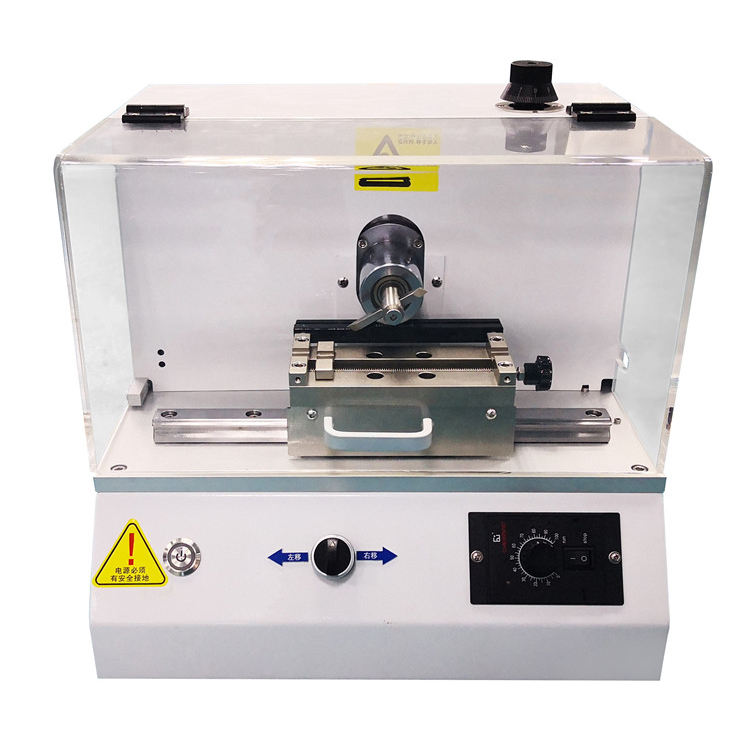

This equipment is an electro-hydraulic driven punch press for preparing specimens for tensile testing and other tests on sheet materials. It is used for preparing dumbbell tensile specimens and cold-bent straight bar specimens from hot-rolled sheets (thickness: 0.2mm-3.0mm.. It employs stable pressure hydraulic control, ensuring high precision in specimen punching. The process is automated, stable, fast, and reliable. This equipment features an advanced structure and is easy to use.

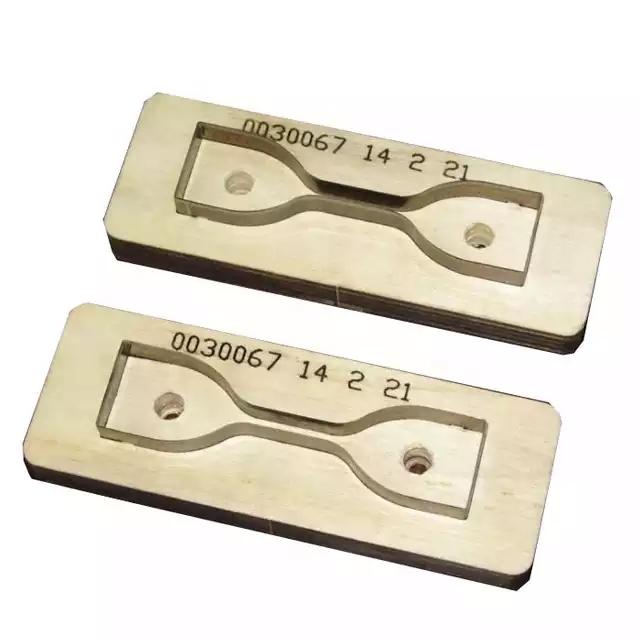

1. The punch press mainly consists of three parts: the machine body, the hydraulic station, and the die;

2. The machine body mainly includes: a support frame, a C-shaped load-bearing bracket, a T-shaped rolling operating table, hydraulic cylinders, and operating buttons;

3. The hydraulic station is low-noise, compact, and housed within the equipment;

4. The die is replaced using a front-and-rear push-pull method, which is convenient and quick. The ball bearing operating table reduces labor intensity.

Features:

1. Safety: Operational safety protection: To ensure operator safety, the mold has an anti-finger insertion device to prevent fingers from entering; System safety protection: The hydraulic system has a pressure relief valve for protection, and the electrical system has safety limit protection;

2. Convenience: Sample delivery—press switch—material unloading complete—sample removal (sample slides out from the punch press chute.;

3. Time saving: The die completes one punching process in 6 seconds; One punching process can punch one sample;

4. Precision: The shape tolerance of the parallel part is less than 0.02mm; The hardening influence zone on the sample during punching is small;

Main Parameters:

|

Model |

HST-LC1100 |

|

Nominal force |

1100KN |

|

The thickness of the stamped sheet material |

≤3.0mm |

|

Sampling speed |

6s/piece |

|

Sample size tolerance |

±0.02mm |

|

The left and right sides of the workbench |

1560mm |

|

The workbench front and back |

700mm |

|

Motor power |

5.5KW |

|

The height of the workbench from the ground |

680mm |

|

Cylinder stroke |

50mm |

|

Gear pump |

10ml/r |