Non-Contact Video Extensometer

Non-Contact Video extensometer

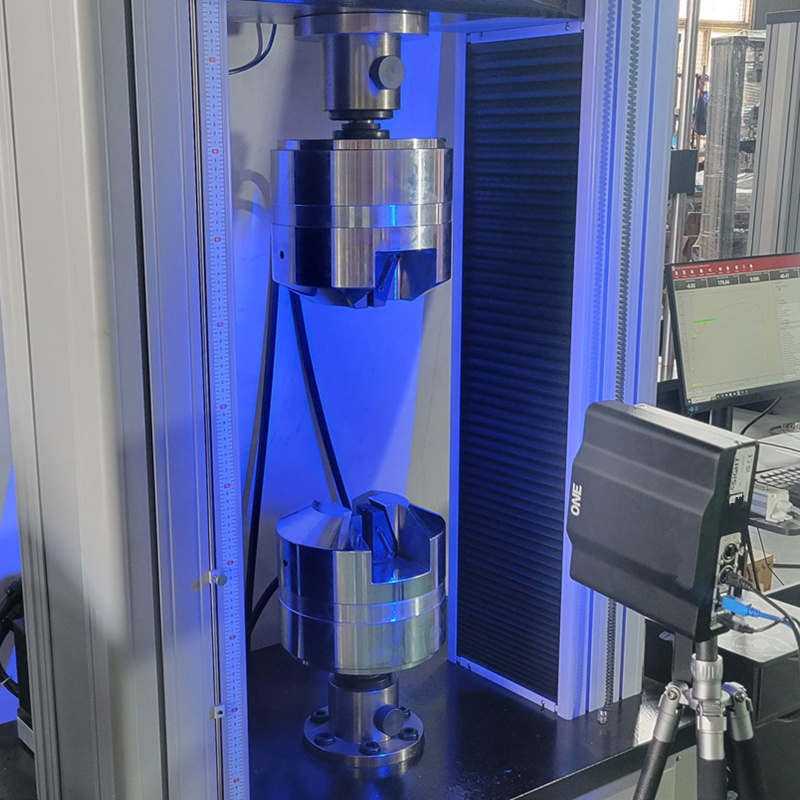

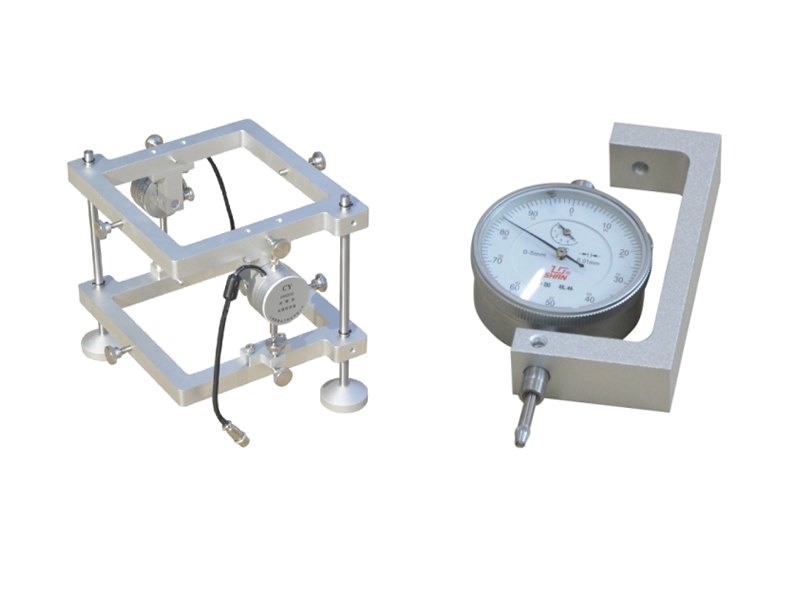

Versatile non-contact Extensometer range for uniaxial and biaxial testing.

Automatic, pre-calibrated, intelligent and self-contained. Cost-effective solution to replace clip-on extensometers in QA/QC and R&D. Accurate and comprehensive to efficiently deliver reliable real-time strain.

For all the aspects above, all Vectors:

Meet or exceed ISO 9513 Class 0.5 and ASTM E83 Class B-1, and

Operate reliably when testing at temperature, ranging from -100 °C to +370 °C, and

Are compliant to ISO 6892 and ASTM E8 strain-rate control for quasi-static testing, and

Seamlessly output real-time strain or extension data via serial D-Sub or ±10V BNC.

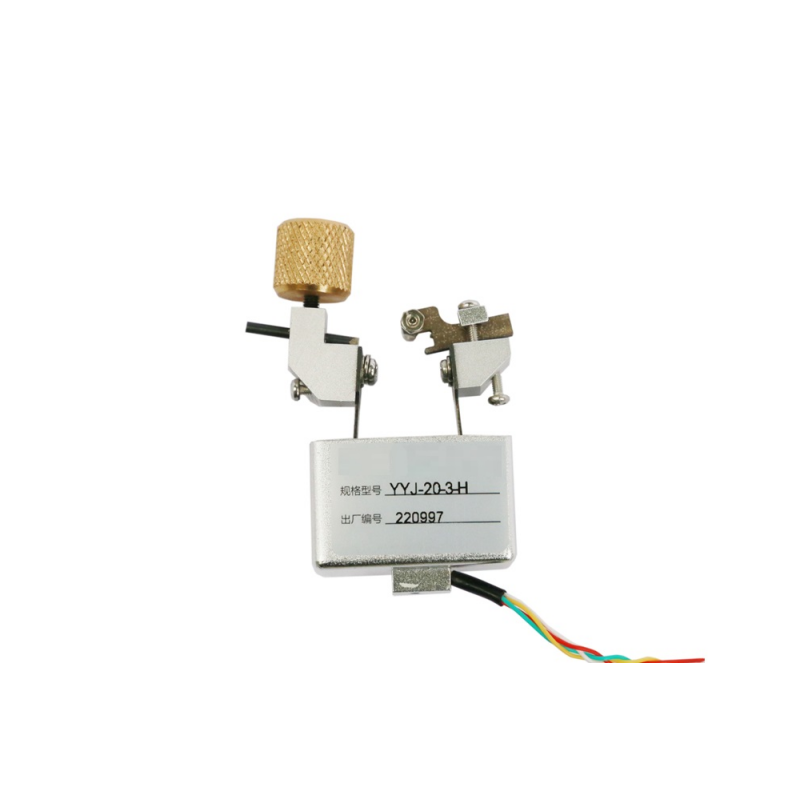

Non-contact Extensometer

Versatile non-contact extensometer

range for uniaxial and biaxial testing.

Automatic, pre-calibrated, intelligent and

self-contained.

Cost-effective solution to replace clip-on

extensometers in QA/QC and R&D.

Accurate and comprehensive to

efficiently deliver reliable real-time strain. Measuring the Industrial World

www.hssdgroup.com

Page: 2

The Smarter Alternative to Clip-On Extensometers

Suitable for all applications where traditional clip-on extensometers are used, Vector offers key

advantages that enhance testing accuracy, efficiency and value.

Consistent and Reliable Data

Fully compliant with ISO and ASTM standards.

Non-contact measurement eliminates the risk of test interference.

No operator handling – removes human error.

No knife edges – nothing to wear out or slip.

Lower Cost of Ownership

One Vector can measure multiple gauge lengths, reducing the need for multiple devices.

Significantly lower calibration and maintenance costs over time.

Non-contact design reduces the risk of device damage.

Higher Testing Efficiency

Versatile: Compatible with a wide variety of specimen types.

Fast setup: Ready for testing in just 40 seconds.

Quick acquisition: Acquires the next specimen in just 2 seconds.

Enables uninterrupted testing to failure.

Representative maximum strain range and extension for selected gauge lengths