ASTM D5035 Breaking Strength and Elongation of Textile Fabrics (Strip Method)

ASTM D5035 Breaking Strength and Elongation of Textile Fabrics (Strip Method)

ASTM D5035 provides a testing procedure for determining the maximum force and elongation at maximum force of various textile fabrics using raveled strip and cut strip methods of testing. If required, the force and elongation at rupture are recorded as well.

The raveled testing method is mainly applicable to woven fabrics, whereas the cut strip test is mainly applicable to nonwoven, dipped or coated fabrics, and felted fabrics. However, the methods from this testing procedure are not meant for knitted fabrics or others with high breaking elongation. It is important to review the full standard in order to fully understand the test setup, procedure, and results requirements.

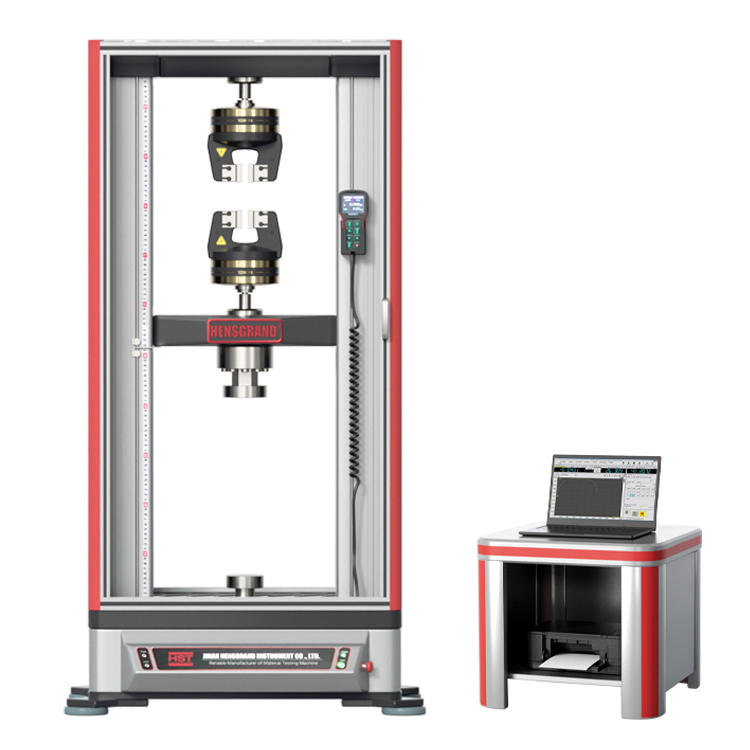

Materials Testing System

As with most textiles testing, it is important to consider data rate when choosing a testing instrument. To consistently and accurately measure the tear strength of your material, it is important to remember that the data sampling rate needs to be high enough that the test peaks and troughs are adequately captured. We recommend HST’s high tier WDW-E Series systems due to their data capture rate of up to 5 kHz. For most textile fabrics testing to ASTM D5035, a single column frame is appropriate as the loads rarely go above 5 kN.

ASTM D5035 provides a testing procedure for determining the maximum force and elongation at maximum force of various textile fabrics using raveled strip and cut strip methods of testing. If required, the force and elongation at rupture are recorded as well.

The raveled testing method is mainly applicable to woven fabrics, whereas the cut strip test is mainly applicable to nonwoven, dipped or coated fabrics, and felted fabrics. However, the methods from this testing procedure are not meant for knitted fabrics or others with high breaking elongation. It is important to review the full standard in order to fully understand the test setup, procedure, and results requirements.

Materials Testing System

As with most textiles testing, it is important to consider data rate when choosing a testing instrument. To consistently and accurately measure the tear strength of your material, it is important to remember that the data sampling rate needs to be high enough that the test peaks and troughs are adequately captured. We recommend HST’s high tier WDW-E Series systems due to their data capture rate of up to 5 kHz. For most textile fabrics testing to ASTM D5035, a single column frame is appropriate as the loads rarely go above 5 kN.