ASTM D638: The Definitive Guide To Plastic Tensile Testing

ASTM D638 is the most common testing standard for determining the tensile properties of reinforced and non-reinforced plastics. With the use of plastics being at an all-time high, it is critical that manufacturers be able to properly gauge the mechanical strength of their materials. This guide is designed to introduce you to the basic elements of an ASTM D638 plastic tensile test, including an overview of the equipment, software, and samples needed. However, anyone planning to conduct ASTM D638 testing should not consider this guide an adequate substitute for reading the full standard.

What Does it Measure?

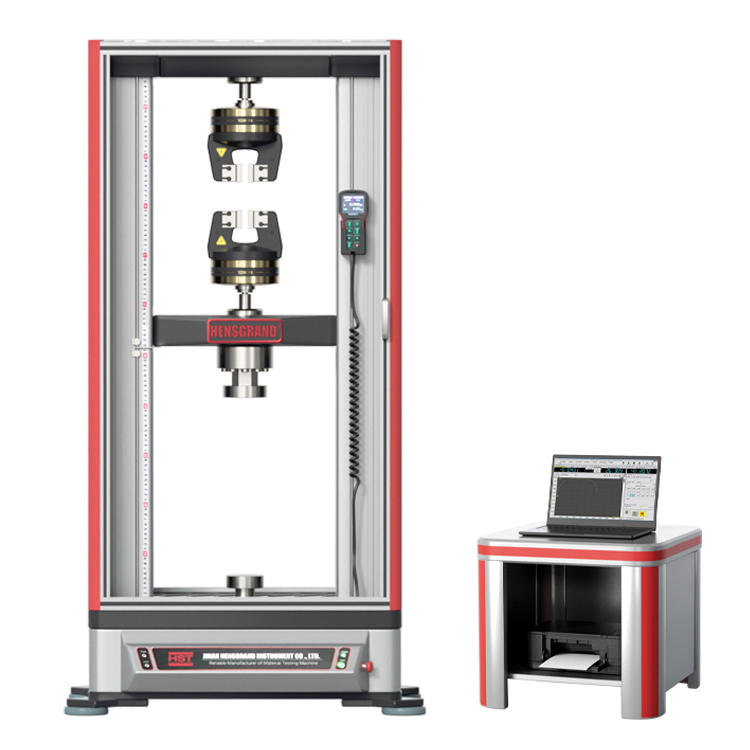

ASTM D638 is performed by applying a tensile force to a sample specimen and measuring various properties of the specimen under stress. It is conducted on a Universal Testing Machine (also called a tensile testing machine) at tensile rates ranging from 1 to 500 mm/min until the specimen fails (yields or breaks). Though ASTM D638 measures many different tensile properties, the following are the most common:

Tensile strength – the amount of force that can be applied to a plastic before it yields (stretches irreparably) or breaks.

Tensile modulus – how much a material can deform (stretch) in response to stress before it yields. Modulus is a measurement of the material’s stiffness.

Elongation – the increase in gauge length after break divided by the original gauge length. Greater elongation indicates higher ductility.

Poisson’s Ratio - a measurement of the relationship between how far a material is stretched and how thin it gets during the stretching process.

What Does it Measure?

ASTM D638 is performed by applying a tensile force to a sample specimen and measuring various properties of the specimen under stress. It is conducted on a Universal Testing Machine (also called a tensile testing machine) at tensile rates ranging from 1 to 500 mm/min until the specimen fails (yields or breaks). Though ASTM D638 measures many different tensile properties, the following are the most common:

Tensile strength – the amount of force that can be applied to a plastic before it yields (stretches irreparably) or breaks.

Tensile modulus – how much a material can deform (stretch) in response to stress before it yields. Modulus is a measurement of the material’s stiffness.

Elongation – the increase in gauge length after break divided by the original gauge length. Greater elongation indicates higher ductility.

Poisson’s Ratio - a measurement of the relationship between how far a material is stretched and how thin it gets during the stretching process.