ASTM D695 Composites & plastics Compression test

ASTM D695 is a test method used to determine the compressive properties of un-reinforced and reinforced plastics. It is used alongside its tensile test standard equivalent, ASTM D638.

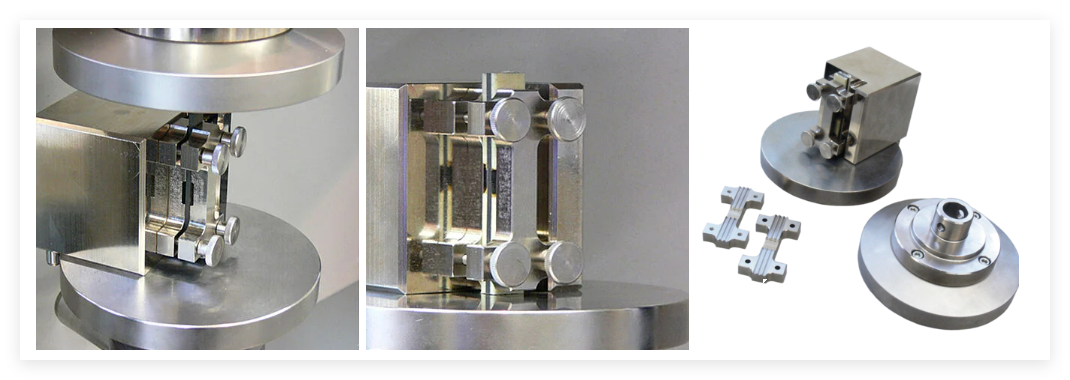

The following characteristic results and values for fiber-reinforced plastics can be determined with the compression test according to ASTM D695 with compression support and in particular with the variants developed from ASTM D695 (EN 2850 Method B, SACMA SRM-1R-94, Boeing BSS 7260 Type III & IV):

Compressive stress: compressive force related to the initial cross section of the specimen

Compressive strain: change in gauge length in relation to the initial gauge-length in the load direction (only when using a suitable measurement system, see below)

Compressive modulus: slope of the stress-strain diagram in a specified strain interval in the elastic range. Also called modulus of elasticity or Young’s modulus

Compressive strength: maximum compressive stress carried by a specimen during a compression test

What Does this Standard Measure?

ASTM D695 obtains the properties of a material's compressive strength, compressive yield point, and modulus. The standard specimen for strength determination is a right cylinder or prism whose length is twice its principal width or diameter. If the specimen is too thin, an anti-buckling support jig should be used to prevent the specimen from buckling.

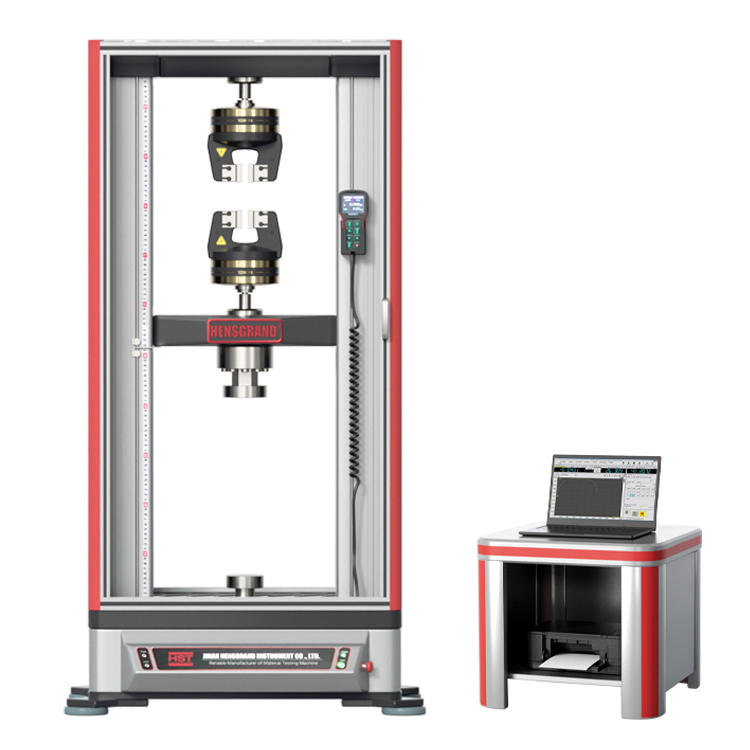

Materials Testing System

Depending on the maximum expected forces, ASTM D695 can be performed on either a single column or dual column universal testing machine such as those available in HST WDW-E Series.