- Electronic Universal Testing Machine

- Hydraulic Universal Testing Machine

- Dynamic Fatigue Testing System

-

Horizontal Tensile Testing Machine

-

Robot Automated Testing Systems

- Impact Testing Machine Series

- Compression Testing machine

- Torsion Testing Machine

- Bending Testing Machine

-

Creep and Rupture Testing Machine

-

Elastomeric Bearing Testing Machine

- Spring Testing Machine

-

Insulator Testing Machine

- Metallographic

- Hardness Tester

- Microscope

-

Plastic Pipes and Rubber Test Machine

- Melt Flow Index Tester

- HDT&VICAT Softening Point Temperature Tester

- Pendulum Impact Tester

- Hydrostatic Pressure Tester

- Plastic Pipes Ring Stiffness Tester

- Differential Scanning Calorimeter

- Moisture Meter

- Density Tester

- Ash Content Tester

- Falling Mass Impact Testing Machine

- Methylene Chloride Soak Tester

- Flame Resistance Tester

- Milling Machines

- Rubber industry testing equipment

- Environmetal Test Chamber

- Optical Spectrometer

-

Other testing equipment

- Testing equipment for masks and protective Cover

- High And Low Temperature Test Chamber

- NDT Equipment Series

- Vision Measuring Machine

- Optical Profile Projector

- Coordinate Measuring Machine

- Paper and Package Test Tester

- Textile Test tester

- Optical Test Machine

- Cupping Testing Machine

- Bolt testing equipment

- Friction and wear testing machine

- Voltage Breakdown Tester

- Torque rheometer

- Capillary rheometer

- Plastic Friction and Wear Testing Machine

- Testing machine accessories

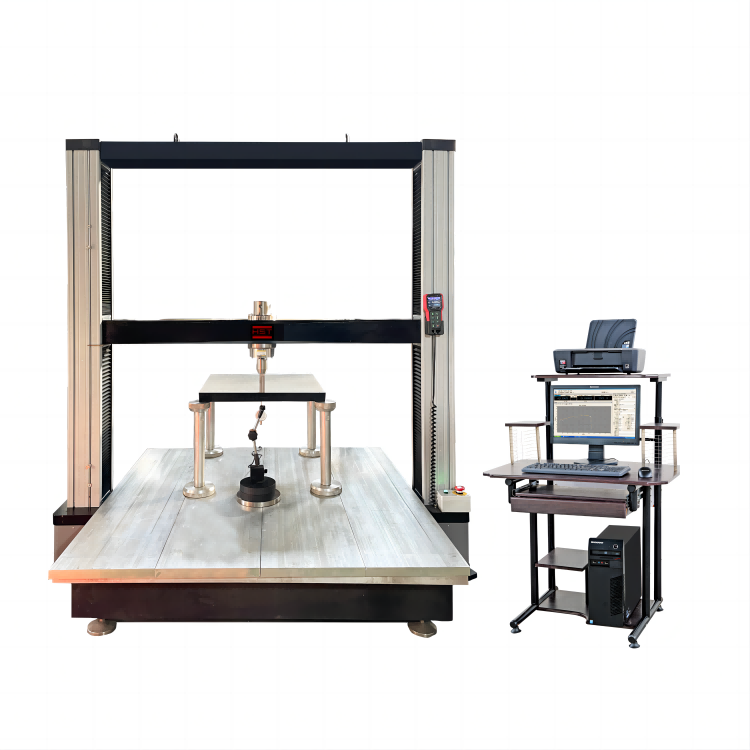

Tensile Test of Plastics Composites And Extrusion (ISO 527)

Application:

Universal tensile test machine/Determination of tensile properties for moulding and extrusion plastics is used to test the mechanical properties of various materials such as static load, tensile, compression, bending, shearing, tearing, peeling and other mechanical properties of mechanical equipment. It is suitable for plastic plates, pipes, and other materials. Various physical and mechanical performance tests of profiles, plastic films and rubber, wires and cables, steel, fiberglass and other materials are developed for materials.

The test methods of ISO 527-1 can be used to test a wide variety of plastic materials, including:

- Thermoplastics for molding and extruding.

- Thermosetting molding materials

- Fiber reinforced thermoset and thermoplastics composites

- Thermotropic liquid crystal polymers

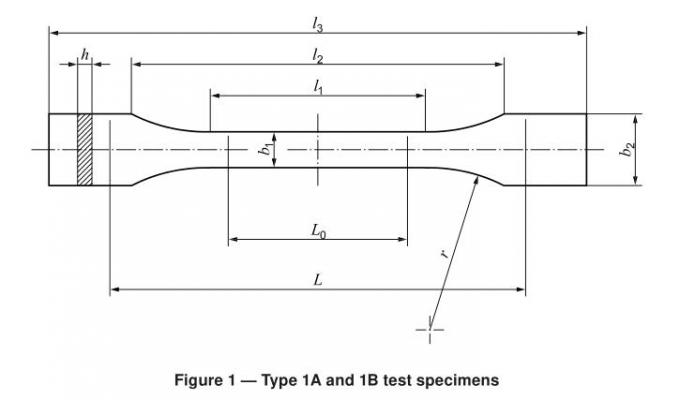

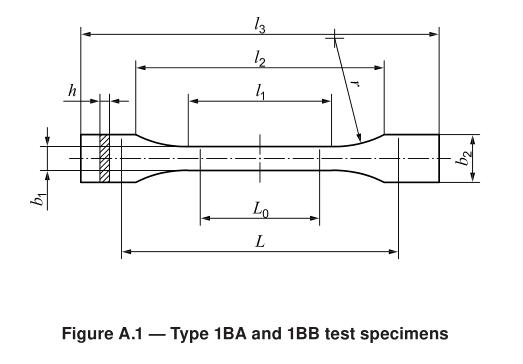

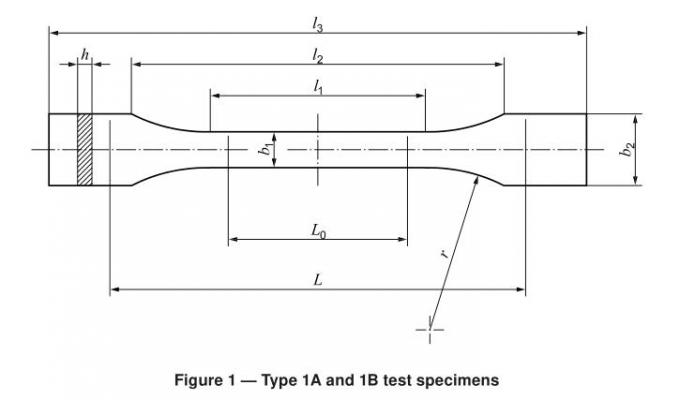

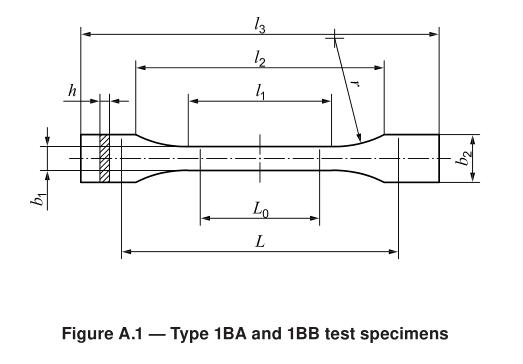

According to ISO 527-1, tensile testing of plastics is executed by pulling a test specimen along a major longitudinal axis at a constant rate of extension until failure of the plastic specimen occurs or until a predetermined stress or strain value. ISO 527-1 requires stress and strain measurements to be recorded through the plastic tensile test.

Plastic tensile test specimens are to be used to testing in accordance to ISO 527-1. Plastic components are not tested with the practices of ISO 527-1. The purpose of ISO 527-1 is to determine tensile properties of plastics, and not to determine stress behavior of plastic components.

Standards:

ISO 527, ISO 6259, GB/T 1040, ISO7500-1, ISO 5893,ISO 9969, ISO 13586

Main technical parameters

| Model | HSTWDW-10E |

| Type | Double column model |

| Accuracy Grade | Class 0.5 |

| Force-measuring Range | 0.4%~100%FS |

| Deformation-measuring Range | 2%~100%FS |

| Deformation-measuring Accuracy | ±1% |

| Crossbeam Displacement Resolution | 0.001mm |

| Crossbeam Speed Range | 0.05~1000mm/min |

| Displacement Speed Accuracy | ≤ ±0.5% |

| Metal Extensometer Accuracy Grade | ±0.5% |

| Test width | 380mm |

| Tensile Space | 700mm |

| Compression Space | 1000mm |

| Clamps | Tensile, compression, bending fixture |

| PC System | Equiped with brand computer |

| Power Supply | AC 220V±10%, 50Hz (can be customized as customer request) |

| Size of the host | 700*400*2000mm |

| Packing size & Weight | 800*500*2100mm,about 350kg |