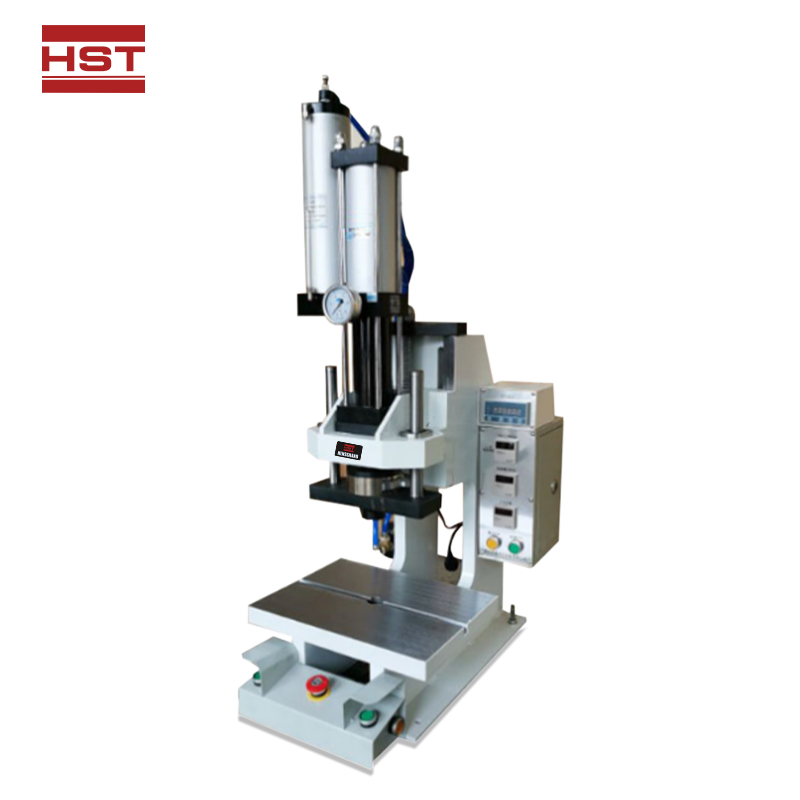

HST-LE series Large throat deep gas-liquid booster press machine

The gas-liquid booster press machine requires no hydraulic system; it only needs 4-7 kg of compressed air to generate a high-pressure output force of 1-20T.

Standards:

ISO,ASTM

Request A Quote Files DownloadLarge throat deep gas-liquidbooster press machine HST-LE series

Working principle and application

The gas-liquid booster press machine requires no hydraulic system; it only needs 4-7 kg of compressed air to generate a high-pressure output force of 1-20T. It uses a pneumatic-hydraulic booster cylinder and a pneumatic-electric control unit as the power actuator. After connecting to a 220V power supply, the high-pressure gas generated by the compressor is delivered to the electromagnet via an air supply pipe. The movement of the electromagnet, controlled by a foot switch or other control methods, controls the working state of the pneumatic-hydraulic booster cylinder on the machine, completing punching and other processing operations. By changing different molds, it achieves multi-purpose economic benefits. Currently, it is widely used in metal stamping, tight assembly, riveting connections, embossing, bending profiles, profile welding, extrusion forming, flattening and straightening, riveting and forging, sheet metal forming, mold punching, and steel cutting.

Technical parameters

|

Parameters/Pressure |

Unit |

HST-LE-02 |

HST-LE-03 |

HST-LE-05 |

HST-LE-08 |

HST-LE-10 |

|

Preload stroke |

mm |

100 |

100 |

100 |

100 |

100 |

|

Boosting stroke |

mm |

10 |

10 |

10 |

10 |

10 |

|

Action frequency |

times/minute |

25-30 |

25-30 |

25-30 |

20-25 |

20-25 |

|

Driving method |

High-pressure air drives the booster cylinder to perform oil-gas conversion for press-fitting operations. |

|||||

|

Power connection |

V |

Single-phase AC220V, 50HZ |

||||

|

Ambient temperature |

℃ |

0~40 No fogging |

||||

|

Closure height D |

mm |

210-300 |

210-300 |

210-300 |

220-350 |

220-360 |

|

WorkbenchSize J*I |

mm |

400*300 |

400*300 |

400*300 |

400*300 |

450*340 |

|

Deep throat C |

mm |

130/240 |

130/240 |

130/240 |

130/220 |

160/230 |

|

Mold shank hole size F |

Ø |

25H7 |

25H7 |

25H7 |

30H7 |

30H7 |

|

Pressure holding time |

s |

0-9999 |

||||

|

Operation method |

|

Double button/foot switch |

||||

|

Control Mode |

|

Molding mode/Pressure fitting mode |

||||

|

Safety protection |

|

Two-hand switch/Safety light grid |

||||

|

T-slot width G |

mm |

12 |

12 |

12 |

12 |

14 |

|

Mounting hole spacing T*B |

mm |

450*300 |

450*300 |

450*300 |

450*300 |

500*300 |

|

Mounting hole diameter R |

Ø |

12 |

12 |

12 |

12 |

14 |

|

Platform face diameter E |

Ø |

32 |

32 |

32 |

40 |

40 |

|

Base dimensions J*A*H |

mm |

400*640*682 |

400*640*682 |

400*640*682 |

400*650*762 |

450*700*812 |

|

Equipment weight (approx.) |

KG |

175 |

180 |

195 |

245 |

335 |

|

Air source pressure |

Mpa |

0.4-0.7 |

||||

|

Use air pressure |

Mpa |

Theoretical output force (KG) |

||||

|

0.4 |

Mpa |

1230 |

1990 |

4000 |

5020 |

6250 |

|

0.5 |

Mpa |

1540 |

2490 |

5000 |

6280 |

7820 |

|

0.6 |

Mpa |

1850 |

2990 |

6000 |

7530 |

9380 |

|

0.7 |

Mpa |

2160 |

3480 |

7000 |

8790 |

10950 |

|

Remark |

|

Equipment structural parameters can be customized.Red indicates optional accessories, which are not included in the standard model. |

||||

Model Selection Guide

|

Model |

Maximum pressure(T) |

Maximum travel(mm) |

Force Stroke(mm) |

On-Off mode(M/F) |

Pressure digital display |

Safety light grid |

|

HST-LE |

02 |

50 |

5 |

M:Hand-on mode |

S |

G |

|

03 |

100 |

10 |

F:Foot pedal mode |

|

|

|

|

05 |

150 |

15 |

|

|

|

|

|

08 |

200 |

20 |

|

|

|

|

|

10 |

250 |

25 |

|

|

|

|

|

15 |

300 |

30 |

|

|

|

|

|

20 |

|

|

|

|

|

Note: Maximum output force 2000kgf~20000kgf maximum stroke 50mm~300mm can be freely matched, special specifications are accepted for customization.

Example of model selection:HST-LE-02-100-10-M-S-G(Desktop gas-liquid booster press machine;Maximum output force 2000kgf; total stroke 100mm; force stroke 10mm;Hand-on mode;pressure digital display; Safety light grid protection device.)

The pressure digital display device and the safety light grid protection device are optional features. The standard model does not include these two functions unless otherwise specified.

When selecting model, users need to refer to important parameters such as: maximum output force, maximum stroke, actual pressing stroke, throat depth, opening height, fixture table size, and switch control method.

Unless otherwise specified, follow the standard throat depth, opening height and fixture table dimensions.

Customized products are non-standard and require specific details. Please provide your requirements, and our company will create solution tailored to your needs.