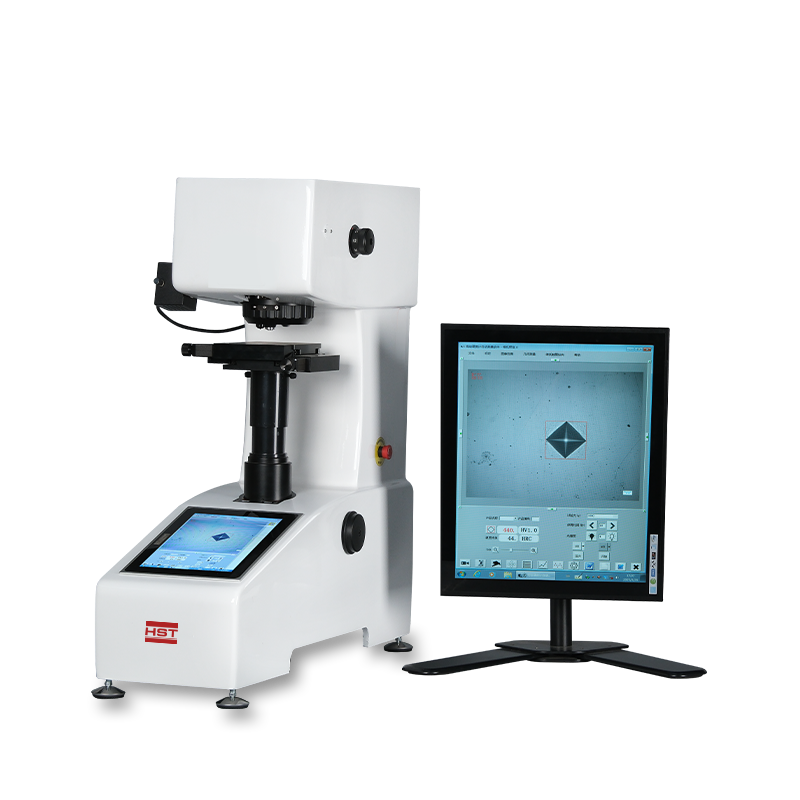

HST-HVS10/50ACT integrated intelligent visual hardness tester

HST-HVS10/50ACT integrated intelligent visual hardness tester1. Steel, nonferrous metals, tinsel, cemented carbide, sheet metal, metallographic structure.2. Carburization, nitriding and decarburizatio

Standards:

Request A Quote Files Download

HST-HVS10/50ACT integrated intelligent visual Hardness Tester

Application:

1. Steel, nonferrous metals, tinsel, cemented carbide, sheet metal, Metallographic structure.

2. Carburization, nitriding and decarburization layer, surface hardening layer, galvanized coating, coating.

3. Glass, chip and ceramic material.

Main features:

Integrated intelligent visual hardness tester, only need to operate a touch tablet computer, easy to get the measurement! And all the parameters required for the test can be selected, modified and analyzed directly on the computer. The PC terminal is connected in series with the Hardness Tester through the communication protocol to realize the control of the mechanical movement of the hardness tester. It can realize: automatic multi-function tower, automatic identification of objective lens and indenter, automatic loading, automatic load preservation, automatic unloading, light brightness. By linking the built-in CCD measurement and acquisition system, it can display clear indentation image dynamics on the PC in real time, and can also directly lock the indentation to automatically measure the hardness value, automatically save the test data, and generate a report. The operation is very simple and fast, eliminating human measurement errors. Integrated intelligent visual hardness tester, with tablet computer as the platform, can expand more application functions through the Internet, and can also be connected to external monitors, printers and other equipment. The side-swing lifting screw adopts a worm gear structure, and the transmission is stable.

1. Industrial tablet computer integration, USB expansion

2. Equipped with the latest Windows operating system,

3. Built-in CCD image automatic measurement system

4. Visual display of indentation and automatic hardness measurement

5. Automatically record measurement data, generate hardness-depth curve, and save it as a WORD file

The machine is equipped with a Vickers automatic measurement control system: it can carry out successive experiments with each load and each indentation read. The convenient ccd camera is used to observe and measure the indentation directly on the display, which has high measurement accuracy and avoids manual measurement errors. For setting test conditions, display results, etc. can be operated and displayed clearly and quickly. Through the measurement control software, it can be easily operated on the built-in computer to realize single-point measurement. Multi-point measurement can be randomly measured, statistical measurement data, and the distance between two or multi-point measurement points can be arbitrarily set for seepage depth measurement along X or Y Two-direction measurement, statistical measurement data, automatic calculation of the hardened layer depth according to the judgment value input by the user. Statistical calculation, conversion, display curve judgment, etc., etc. The length of the measured part can be saved and printed.

Technical parameters:

|

Model |

HST-HVS10ACT |

HST-HVS50ACT |

|

|

Turret |

Automatic 5 position turret (motorized switch) |

||

|

Test force application method |

Automatic (loading, dwell time, unloading) |

||

|

Test force |

0.3Kgf (2.94N), 0.5Kgf (4.90N), 1.0 Kgf(9.8N), 2.0Kgf(19.6N),2.5Kgf(24.5N), 3.0Kgf(29.4N), 5.0Kgf(49.0N), 10.0Kgf(98.0N) |

1.0 Kgf(9.8N), 2.0Kgf(19.6N), 2.5Kgf(24.5N), 3.0Kgf(29.4N), 5.0Kgf(49.0N),10.0Kgf(98.0N)15.0Kgf(147N),20.0Kgf(196N), 30.0Kgf(294N), 40.0Kgf(392N), 50.0Kgf(490N) |

|

|

Hardness Scale |

Vickers |

HV0.3,HV0.5,HV1.0,HV3.0 ,HV5.0,HV10.0 |

HV1, HV5,HV10,HV20,HV30,HV50 |

|

Conversion Scale |

HRA, HRB, HRC, HRD, HRF, HV, HK, HBW, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T |

||

|

Hardness test range |

5-3000HV |

||

|

Unit conversion |

Brinell, Rockwell, Knoop (and switchable: ASTM, ISO, JJG standards) |

||

|

Hardness value |

PC automatically measures hardness |

||

|

Qualified judgment |

The qualified range can be set, and the machine automatically reminds whether it is qualified |

||

|

Language switch |

English systems can be switched at any time |

||

|

Error correction |

The system calibrates the hardness at any time |

||

|

Ruler conversion |

HK (Knoop) |

||

|

Hardness value conversion |

Brinell, Rockwell, Vickers |

||

|

testing report |

Automatic generated |

||

|

Load control |

Auto load, auto hold, auto unload |

||

|

Objective lens and indenter |

Automatic switching |

||

|

Optical channel |

Support dual channel |

||

|

Test force retention time |

5~60s |

||

|

Test force selection |

External force selection knob, test force is automatically displayed on the computer |

||

|

Objective lens magnification |

10×,20× |

||

|

Optical system |

Total magnification (μm): 100× (observation), 200× (measurement); measuring range (μm): 400; |

||

|

Optical system resolution |

0.125μm |

||

|

XYtest bench |

Size (mm): 100×100 Stroke range (mm): 25×25 Minimum reading (mm): 0.01 |

||

|

Maximum height of specimen |

150mm |

||

|

Maximum width of test piece |

120mm |

||

|

Power supply voltage |

AC220V/50HZ |

||

|

Weight |

60kg |

||

|

Appearance size |

620X230X630mm |

||