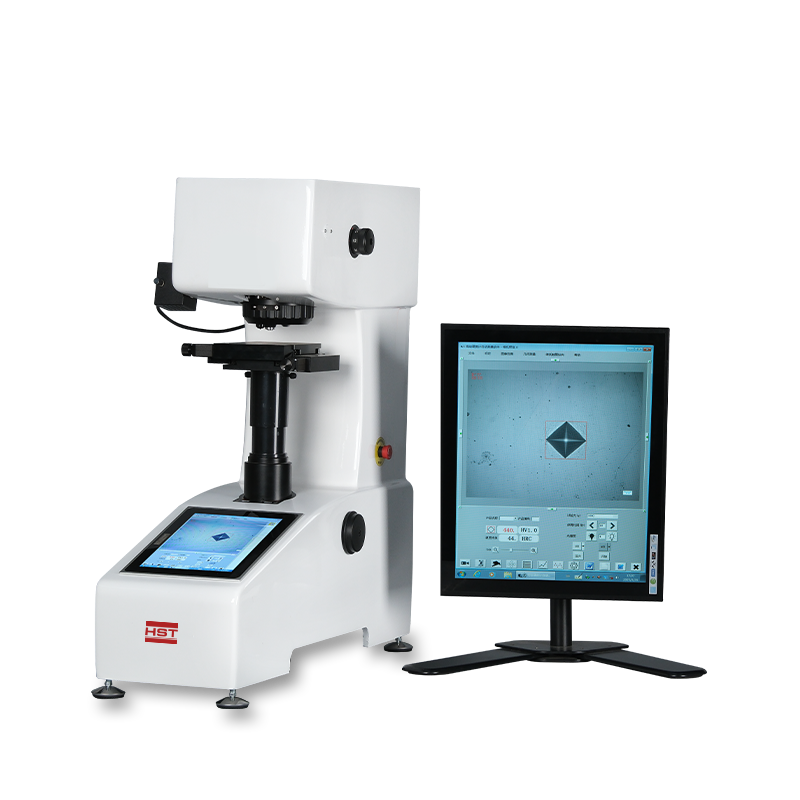

HST-HVS -10I Intelligent Computerized Macro Vickers Hardness Tester

HST-HVS -10I Intelligent Computerized Macro Vickers Hardness Tester

Standards:

Request A Quote Files Download

HST-HVS -10I Intelligent Computerized Macro Vickers Hardness Tester

Application:

1. Steel, nonferrous metals, tinsel, cemented carbide, sheet metal, Metallographic structure.

2. Carburization, nitriding and decarburization layer, surface hardening layer, galvanized coating, coating.

3. Glass, chip and ceramic material.

Main features:

1. Closed loop design with high accuracy load cell, no need to install dead weights, let installation more easy and loading - dwell - unloading automatically, easy operation

2. With load automatic correct function, greatly improved test accuracy and let calibration more easy

3. Modular design, simple maintenance

4. With hardness conversion function, from HV hardness value can covert to HR, HB, HK, etc.

5. With HV/HK test function

6. One-time casting iron molding shell ensure structure more stable; Adopted car painting technology, new appearance design looking more decent; High scratch resistance capability, used for years still brightness like new.

Technical parameters:

|

Model |

HST-HVS -10I |

|

Turret |

Automatic (motorized switch) |

|

Force loading |

Automatic loading - dwell - unloading |

|

Testing Force |

0.1Kgf(0.98N), 0.2Kgf( 1.96N), 0.3Kgf (2.94N), 0.5Kgf (4.90N), 1.0 Kgf (9.8N), 2.0Kgf(19.6N), 2.5Kgf(24.5N), 3.0Kgf(29.4N), 5.0Kgf(49.0N), 10.0Kgf(98.0N) |

|

Hardness Scale |

|

|

Conversion Scales |

HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRH, HRK, HV, HK, HBW, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T |

|

Hardness range |

5-4000HV |

|

Eyepiece |

10X digital eyepiece with built-in encoder, automatic calculate data |

|

Objective |

10X, 20X |

|

Magnification |

100X (measurement), 200X (measurement) |

|

XY work table with digital meter head |

Dim.:100x100 mm, Max. Travel Range: 25x25mm, Moving Resolution Ratio: 0.001mm |

|

Dwell time |

1-99S (1 second per step) |

|

Data output |

Touch screen display |

|

Test space |

130mm x 130mm (Height x Depth) |

|

Power supply |

AC220V,50Hz |

|

Standard |

ISO 6507, ASTM E92, JIS Z2244, GB/T 4340.2 |

|

Overall Dimension |

686*302*526mm |