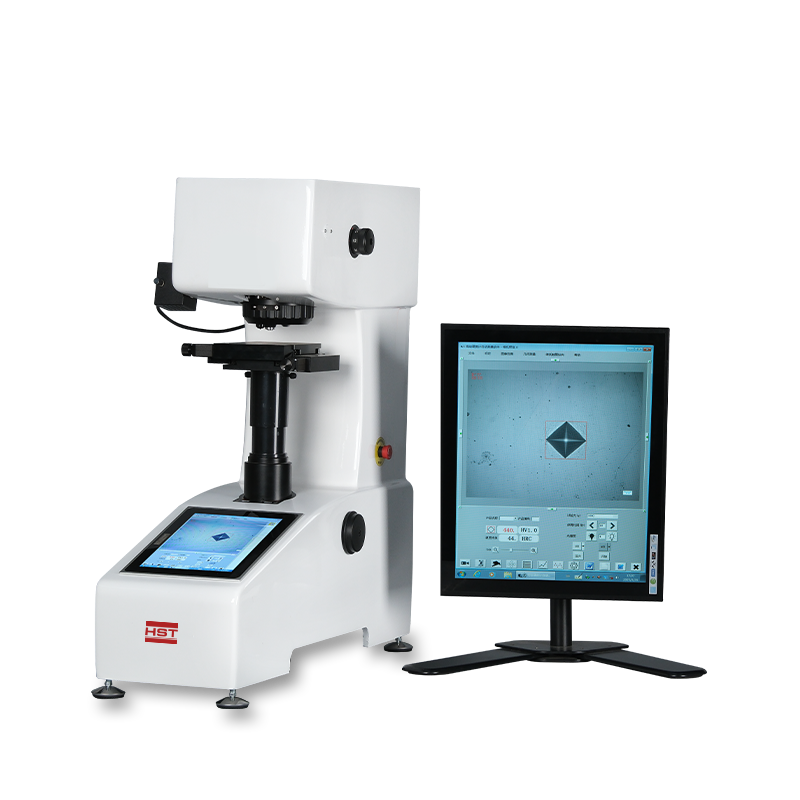

HST-HBRV-STH Series Touch Screen Display Universal Hardness Tester

HST-HBRV-STH Series Touch Screen Display Universal Hardness TesterSuitable for hardened and surface hardened steel, hard alloy steel, casting parts, non-ferrous metals, various kinds of hardening and

Standards:

Request A Quote Files DownloadHST-HBRV-STH Series Touch Screen Display Universal Hardness Tester

Application:

Suitable for hardened and surface hardened steel, hard alloy steel, casting parts, non-ferrous metals, various kinds of hardening and tempering steel and tempered steel, carburized steel sheet, soft metals, surface heat treating and chemical treating materials etc.

Features:

●Adopt 8-inch touch screen, rich display content, easy operation.

●Ready to use after power on, no need to install weights.

●Electronic loading, closed-loop force control, high precision, to ensure the stability and repeatability of test results.

●Three methods of Brinell, Rockwell and Vickers Hardness Test.

●Automatic hardness conversion.

●Equipped with high-precision optical system, can clearly present the indentation to ensure the accuracy of measurement.

●With large storage space, it can store a large amount of measurement data, and can be easily retrieved and printed. Users can view historical test data at any time, conduct data analysis and comparison, and provide strong support for quality control and research work.

Technical Parameters:

|

MODEL |

HST-HBRV187.5STH |

HST-HBRV250STH |

|

Initial Test Force |

Rockwell: 10kgf(98.07N) , Superficial Rockwell: 3kgf(29.4N) |

|

|

Total Test Force |

Rockwell:588.4, 980.7, 1471N (60, 100, 150Kgf) |

|

|

Brinell:49, 98, 153.2, 306.5, 612.9, 1226, 1839, 2452N(5, 10, 15.625, 30, 31.25, 62.5, 125, 187.5Kgf) |

Brinell:49, 98, 153.2, 306.5, 612.9, 1226, 1839, 2452N(5, 10, 15.625, 30, 31.25, 62.5, 125, 187.5, 250Kgf) |

|

|

Vickers:49.03, 98.07, 196.1, 294.2, 490.3, 980.7N(5, 10, 20, 30, 50, 100, 120Kgf) |

||

|

Force Error |

<0.5% |

|

|

Hardness Scale |

Rockwell:HR15N、HR30N、HR45N、HR15T、HR30T、HR45T、HR15X、HR30X、HR45X、HR15Y、HR30Y、HR45Y、HR15W、HR30W、HR45W、HRA、HRB、HRC、HRD、HRE、HRF、HRG、HRH、HRK、HRL、HRM、HRP、HRR、HRS、HRV |

|

|

Brinell: HBW1/5、HBW1/10、HBW1/30、HBW2.5/6.25、HBW2.5/15.625、 HBW2.5/31.25、 HBW2.5/62.5 、HBW5/31.25、HBW10/100、HBW2.5/187.5、HBW5/62.5、HBW5/125HBW5/125,HBW10/100 |

||

|

Vickers:HV3、HV5、HV10、HV20、HV30、HV40、HV50、HV60、HV80、HV100、HV120 |

||

|

Hardness Conversion Scale |

HRA, HRB, HRC, HRD, HRF, HV, HK, HBW, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T |

|

|

Hardness Range |

Rockwell:20-88HRA, 20-100HRB, 20-70HRC; Brinell:5-650HBW; Vickers:5-3000HV

|

|

|

Hardness Resolution |

0.1HBW, 0.1HR,0.1HV |

|

|

Indication Accuracy |

Brinell: ±2.5HB, Rockwell:±0.1HR, Vickers:±2 HV |

|

|

Repeatability |

Brinell:≤3.0HB, Rockwell: 0.5HR, Vickers: ≤2.5HV |

|

|

Magnification |

Eyepiece: 15X, 2.5X (for Brinell), 5X (for Vickers) Total magnification: 37.5X, 75X |

|

|

Dwelling Time |

0~90s Adjustable |

|

|

Test Throat |

160mm |

|

|

Test Height |

Rockwell 180mm;Brinell165mm, Vickers165mm |

|

|

Data Output |

Touchable LCD display, USB Flash Disk / built-in printer |

|

|

Executive Standards |

ISO 6508, ASTM E-18, JIS Z2245, GB/T 230.2,ISO 6506, ASTM E10-12, JIS Z2243, GB/T 231.2,ISO 6507, ASTM E92, JIS Z2244, GB/T 4340.2 |

|

|

Power |

AC 220V+5%, 50-60Hz |

|

|

Machine Dimension |

550*230*780mm |

|

|

Weight |

80kg |

|