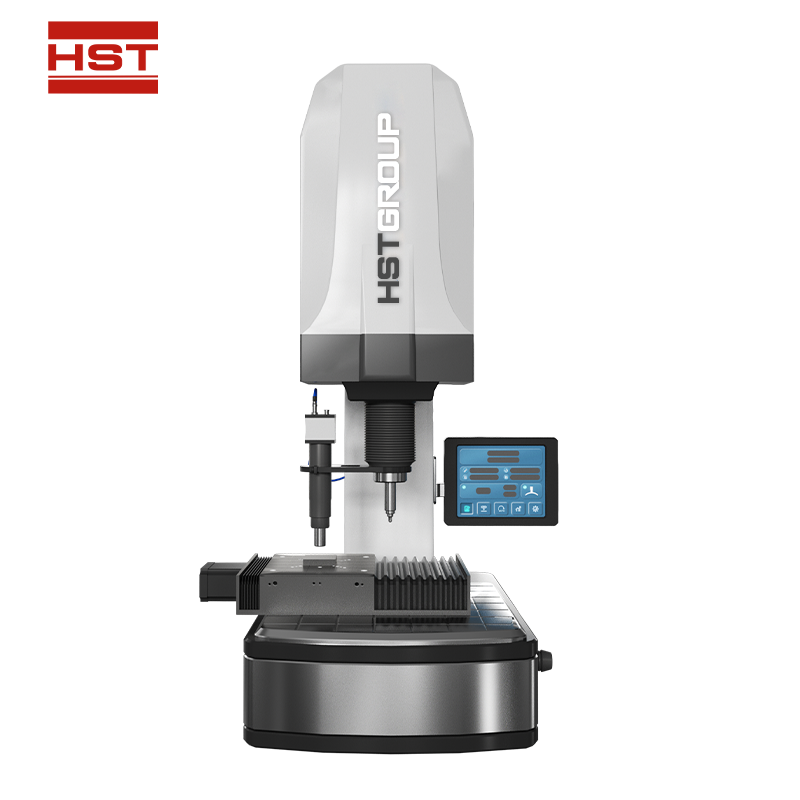

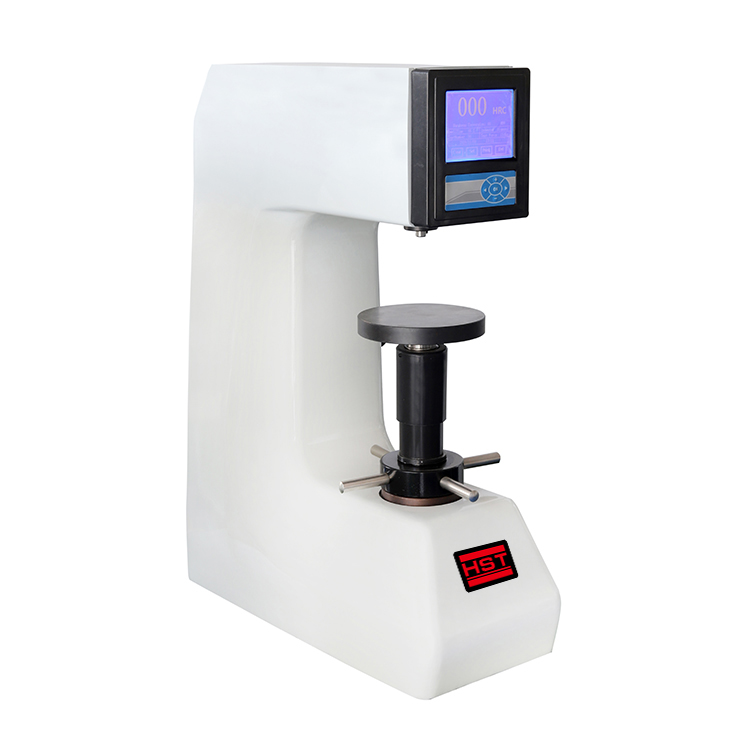

HST-HRS-150/45TN-M Rockwell, Superficial Rockwell Hardness Tester

HST-HRS-150/45TN-M Rockwell, Superficial Rockwell Hardness Tester

Standards:

Request A Quote Files Download

HST-HRS-150/45TN-M Rockwell, Superficial Rockwell Hardness Tester

Product Features:

1.The test force are applied via a closed-loop control unit with a load cell, a DC motor and an electronic measurement and control unit replace traditional dead weights. The result is highly accurate measurements at all test loads up to 0.5%.

2.Simple plug - and - play tech allows for much more quick and easy installation than traditional weights type machine.

3.Automated Z-Axis. Just press START key once, entire test process will be finished automatically. Regardless of the the size of the sample, the position of the sample, the distance between the indenter and sample surface. The sample will be auto-lifted to approach the indenter and finishing testing automatically.

4.Higher precision than handle wheel lifting/dead weights type machines which can be affected by user interaction.

5.Extended dolphin nose allows vertical test height of 300mm and throat depth of 220mm.

6.Integrated casting body with more wide basement leads to permanent stability.

7.Built in micro-printer and USB port to PC

Technical Parameters:

|

Model |

HST-HRS-150/45TN-M |

|

Preload |

29.4N (3kgf) , 98. 1N ( 10kgf) |

|

Total test force |

147. 1N( 15kgf), 294.3N(30kgf), 441.3N(45kgf), 588.4N (60kgf), 980.7N ( 100kgf), 1471N( 150kgf) |

|

Scales |

HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HR15W,HR30W,HR45W, HR15X,HR30X, HR45X, |

|

Load dwell duration |

2~50s, can be set and stored |

|

Resolution |

0. 1HR |

|

Display |

High definition backlight LCD |

|

Operation |

Menu selectable, Membrane keypad |

|

Data statistics |

Avg., Max., Min., S, R |

|

Curved surface auto correction |

|

|

Memory |

Max 400 items of test results stored automatically |

|

Testing Capacity |

300mm (vertical), 220mm (horizontal) |

|

Dimensions |

690mm×280mm×860mm |

|

Power supply |

AC, 220V/ 110V, 50~60Hz, 4A |

|

Net weight |

86kg |

|

Gross weight |

120kg |