- Electronic Universal Testing Machine

- Hydraulic Universal Testing Machine

-

Horizontal Tensile Testing Machine

- Steel Wire Testing Machine

- Dynamic Fatigue Testing System

-

Robot Automated Testing Systems

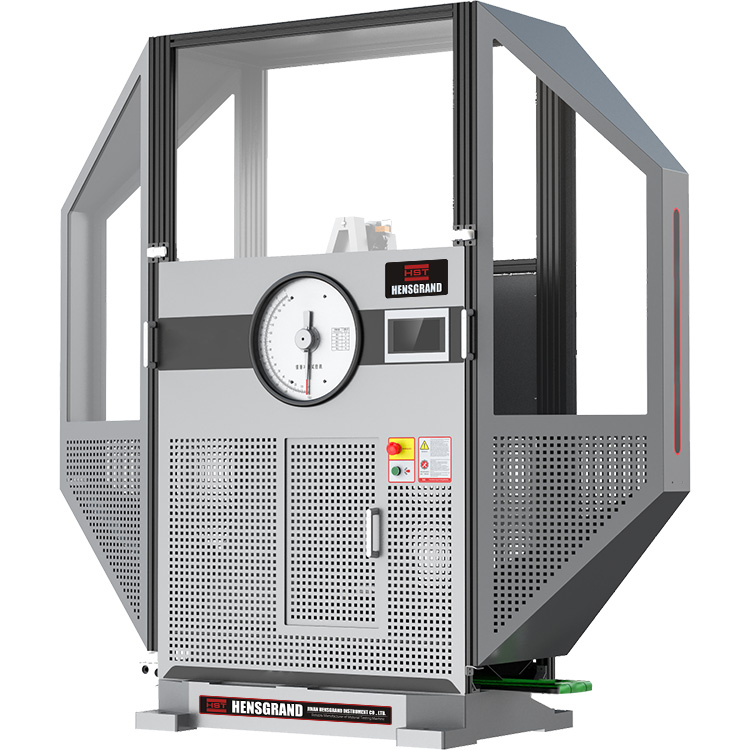

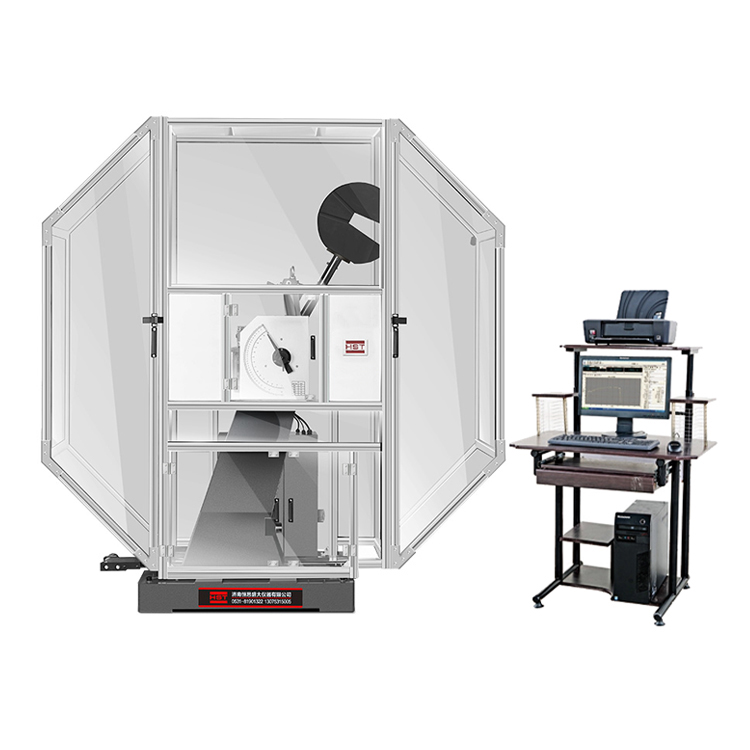

- Impact Testing Machine Series

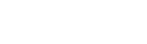

- Compression Testing machine

- Torsion Testing Machine

- Bending Testing Machine

-

Creep and Rupture Testing Machine

-

Erichsen Cupping Testing Machine

-

Elastomeric Bearing Testing Machine

- Spring Testing Machine

-

Insulator Testing Machine

- Metallographic

- Hardness Tester

- Microscope

-

Plastic Pipes and Rubber Test Machine

- Melt Flow Index Tester

- HDT&VICAT Softening Point Temperature Tester

- Pendulum Impact Tester

- Hydrostatic Pressure Tester

- Plastic Pipes Ring Stiffness Tester

- Differential Scanning Calorimeter

- Moisture Meter

- Density Tester

- Ash Content Tester

- Falling Mass Impact Testing Machine

- Methylene Chloride Soak Tester

- Flame Resistance Tester

- Milling Machines

- Rubber industry testing equipment

- Environmetal Test Chamber

- Intellectual_Product

- Optical Spectrometer

-

Other testing equipment

- Testing equipment for masks and protective Cover

- High And Low Temperature Test Chamber

- NDT Equipment Series

- Vision Measuring Machine

- Optical Profile Projector

- Coordinate Measuring Machine

- Paper and Package Test Tester

- Textile Test tester

- Optical Test Machine

- Bolt testing equipment

- Friction and wear testing machine

- Voltage Breakdown Tester

- Torque rheometer

- Capillary rheometer

- Plastic Friction and Wear Testing Machine

- Testing machine accessories

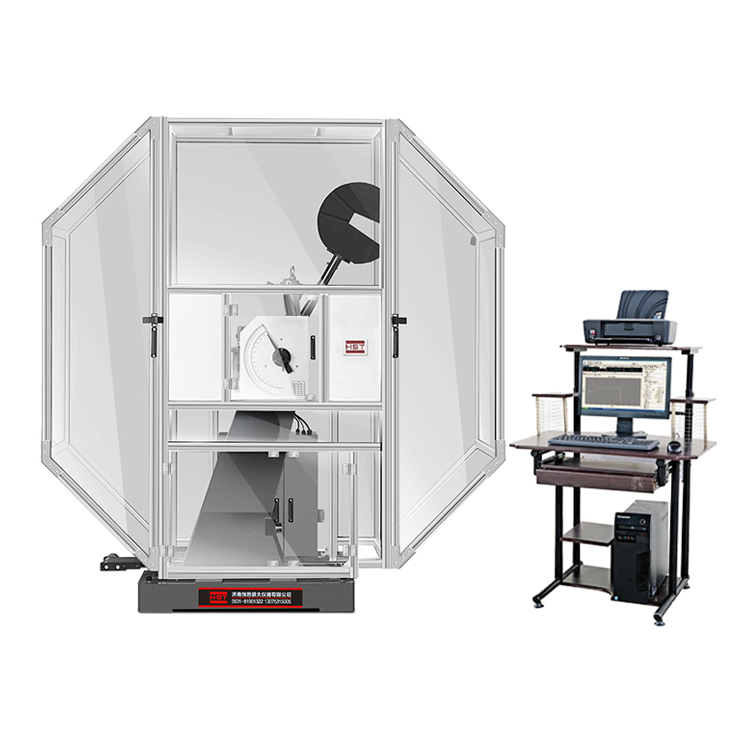

JBW-C Computer Control Charpy Impact Tester(300J~750J)

Application:

JBW-C Charpy Impact Testing Machine is mainly used to to measure impact absorbing energy and impact toughness of metal material.

Advantages

1.Main frame and foundation is integration, good stiffness and high stability.

2.Round pendulum makes wind resistance to mini.Impact knife adopts wedge block to compress and install.It is easy to exchange.

3.Suspension pendulum device adopts hydraulic buffer to avoid damage and low noise when hang pendulum.It extends service life and improves safety.

4.Adopts reducer to transport. Its structure is simple, easy to install and maintain, long service life and low breakdown rate.

5.It has samples recycling device. The device outputs broke sample from testing machine after impact to avoid tester to recycle broke sample from testing machine and improve efficiency and safety.

6.It has totally closed safety net to avoid broke sample to splash and tester to approach testing machine when processing test and ensure tester and equipment safe.

Standards

ISO148, EN10045, ASTM E23, GB/T3808-2002 ,GB/T229-2007.

Specifications

MODEL

JBW-300C

JBW-450C

JBW-600C

JBW-750C

Max. impact energy(J)

300

450

600

750

Pendulum torque(N·m)

M=80.3848

M=160.7695

M=241.1543

M=321.5390

Raised angle(mm)

150°±1°

Distance from the axis of support to the center of percussion(mm)

750

Impact speed(m/s)

5.24

Standard span(mm)

40

Round angle of the jaw

R (1.0~1.5)mm (1mm is special ordered.)

Angle of Taper of Supports

11°±1°

Angle of Striking Tip

30°±1°

Thickness of Striking(mm)

16

Round corner of support jaw

R (1.0~1.5)mm (1mm is special ordered.)

Blade curvature radius

R (2.0~2.5)mm (8mm is special ordered.)

Standard specimen dimension(mm)

55x10x10 , 55x10x7.5 , 55x10x5

Power supply

3phs, 380V/220V±10%, VAC50Hz or specified

Dimensions (mm)

Gross weight(KG)