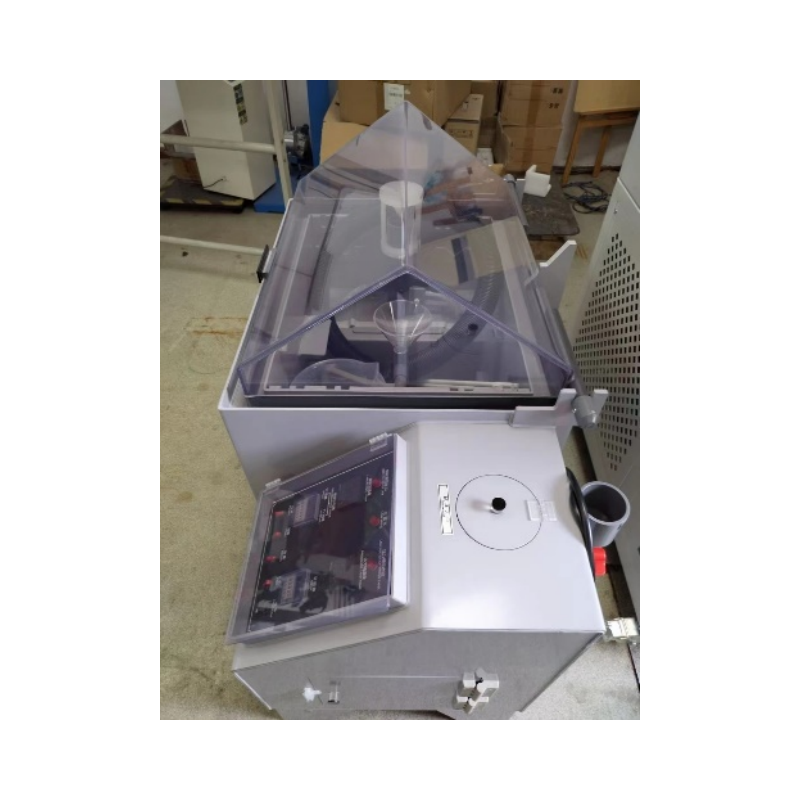

HST-SC60G SC90G SC120G SC200G Salt Spray Test Chamber

The product is suitable for parts/electronic components/metal material protection layer and industrial products salt spray corrosion test chamber

Standards:

CNS3672、3885、4159、7669、8886/ JIS D-0201、H-8502、H-8610、K-5400、Z-2371/ ISO3768、3769 / ASTM B-117、B-268 / GB-T2423 / GJB150

Request A Quote Files DownloadHST-SC60G SC90G SC120G SC200G Salt SprayTest Chamber

Product Introduction

Salt spray test chamber through the assessment of the material and its protective layer salt spray corrosion ability, as well as similar protection layer process quality comparison, at the same time can assess the salt spray corrosion resistance of some products; The product is suitable for parts/electronic components/metal material protection layer and industrial products salt spray corrosion test chamber

Function

· Salt spray, drying, wetting, soaking, constant temperature and humidity test

· Salt spray testing machine is suitable for surface treatment of various materials, including coating, electroplating, organic and inorganic skin film, anodic treatment, anti-rust oil, as if after treatment to test the corrosion resistance of their products.

Features

· The whole set is made of imported PVC board, with strong structure, never deformation, and acid and alkali resistance to high temperature and never change

· Automatic/manual water filling system, with automatic/manual water filling function when water level is insufficient, the test is not interrupted, the water level is insufficient warning display.

· Precision glass nozzle fog diffusion evenly, and naturally fall on the test piece, to ensure no crystal salt blocking.

· The control instrument is on the same machine board, easy to operate, and clear at a glance.

· With double overtemperature protection, water level insufficient warning, to ensure safe use.

· Imported temperature controller with manual and automatic control mode, using digital display, PID control, error±0.1℃, maximum setting time up to 999hrs.

· Direct steam heating method is adopted in the laboratory, which can increase temperature quickly and evenly and shorten standby time.

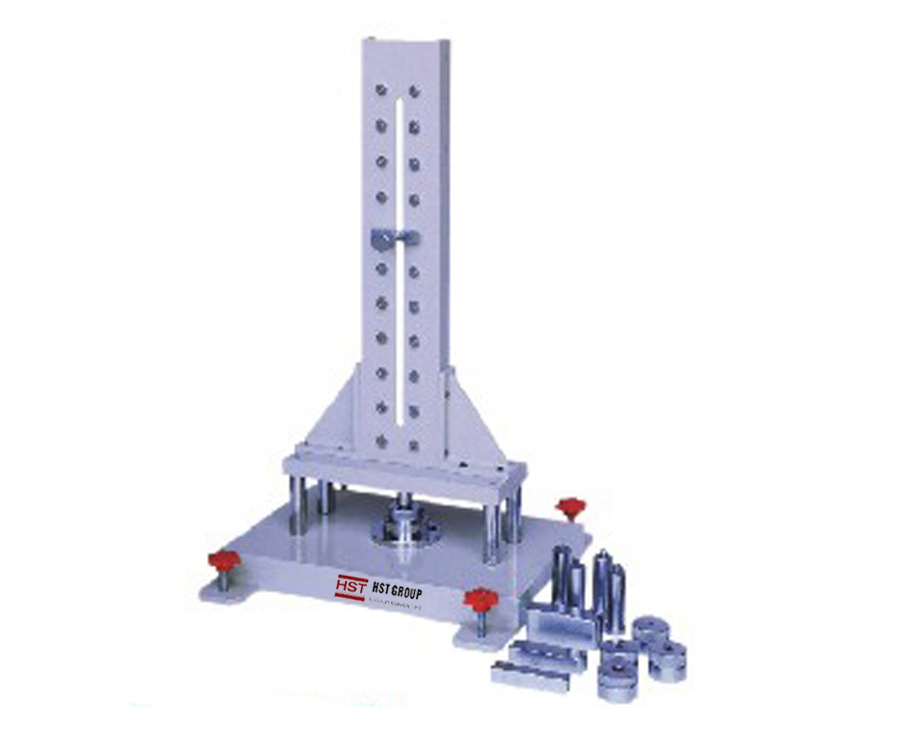

· The spray tower is attached with a conical dispersion device, which can guide the fog, adjust the fog amount and evenly fall the fog.

· The pressure drum is heated and humidified according to Henry's law, and provides the humidity required by the laboratory.

· The upper cover of the test tank for large scale machine is automatically opened and closed by pneumatic cylinder, which is easy to operate and safe.

· After the test is completed, it has an automatic defogging device, which can clearly observe the samples in the test room.

· Standard of use: CNS3672、3885、4159、7669、8886/ JIS D-0201、H-8502、H-8610、K-5400、Z-2371/ ISO3768、3769 / ASTM B-117、B-268 / GB-T2423 / GJB150

Specifications

|

Model/Parameter |

HST-SC60G |

HST-SC90G |

HST-SC120G |

HST-SC200G |

|

1. Test Chamber Dimensions |

60×45×40cm (L*W*H) |

90×60×50cm (L*W*H) |

120*100*50(L*W*H) |

200×100×60cm (L*W*H) |

|

2. External Dimensions |

110×60×95cm (L*W*H) |

143×76×110cm (L*W*H) |

190*130*140(L*W*H) |

273×125×140cm(L*W*H) |

|

3. Volume (L) |

108L |

270L |

600L |

1200L |

|

4. Power Supply |

AC220V |

|

|

|

|

5. Equipment Power |

1.5KW |

2.5KW |

3KW |

4.5KW |

|

6. Lid Opening Method |

Manual opening |

|||

|

7. Test Chamber Temperature Range |

RT+5℃~50℃ |

|||

|

8. Pressure Tank Temperature Range |

RT+5℃~63℃ |

|||

|

9. Temperature Uniformity |

±1℃ |

|||

|

10. Temperature Fluctuation |

±0.5℃ |

|||

|

11. Salt Spray Deposition |

1~2ml/h.80cm2 |

|||

|

12. Spray Pressure |

1.00±0.01kgf/cm² |

0.7~1.2±0.01kgf/cm² |

0.7~1.2±0.01kgf/cm² |

1.00±0.01kgf/cm² |

|

13. Spray Method |

Continuous spray + intermittent spray |

|||

|

14. Salt Water Concentration |

5% |

|||