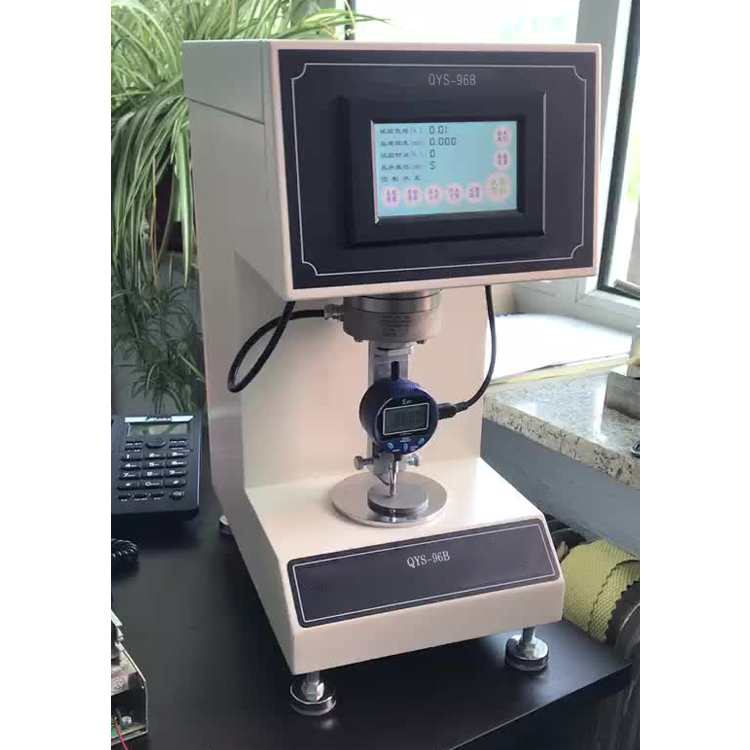

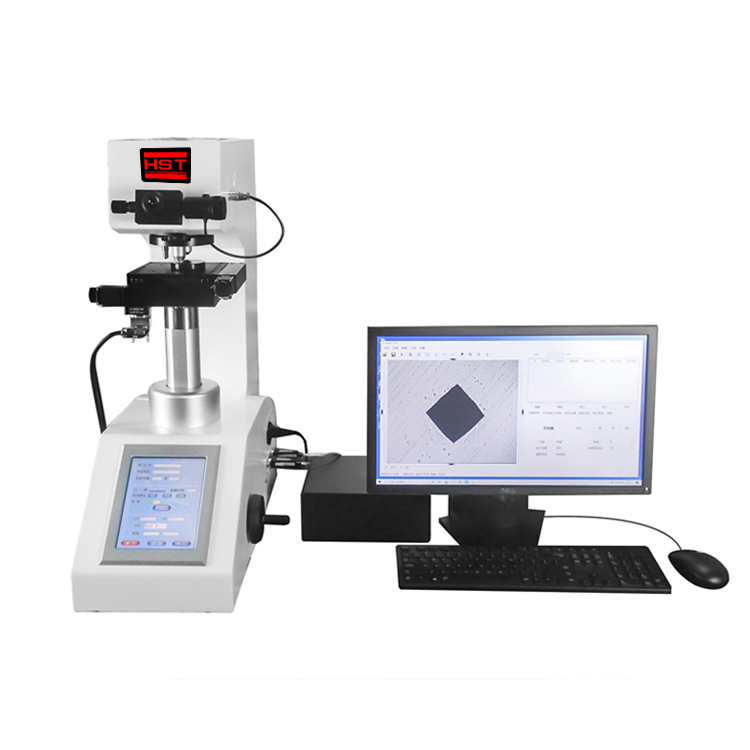

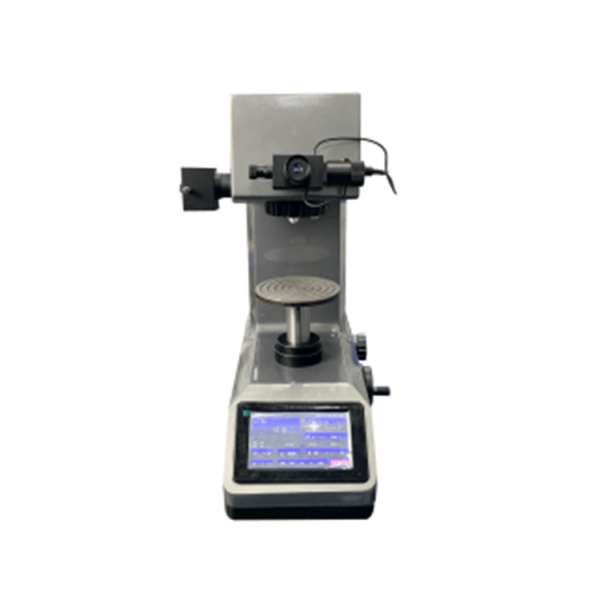

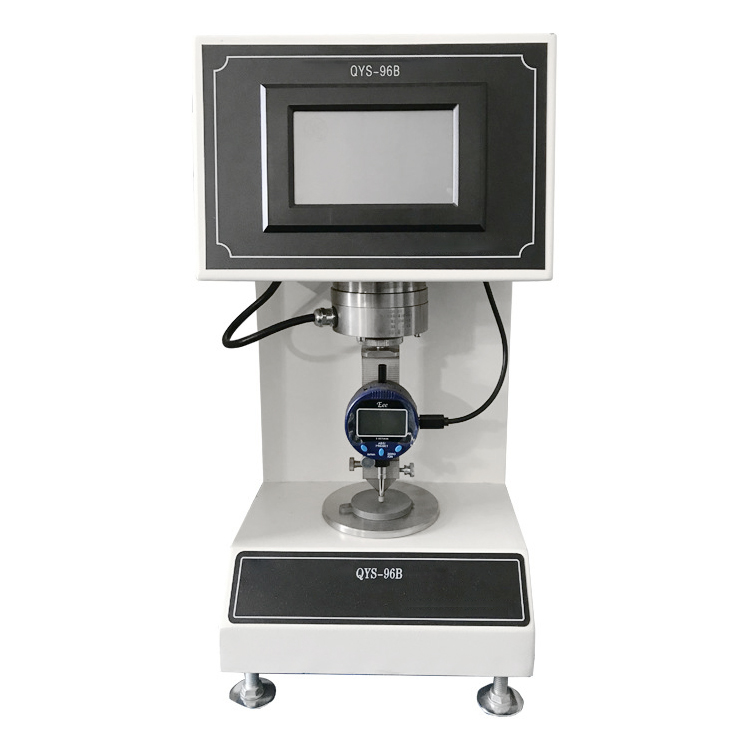

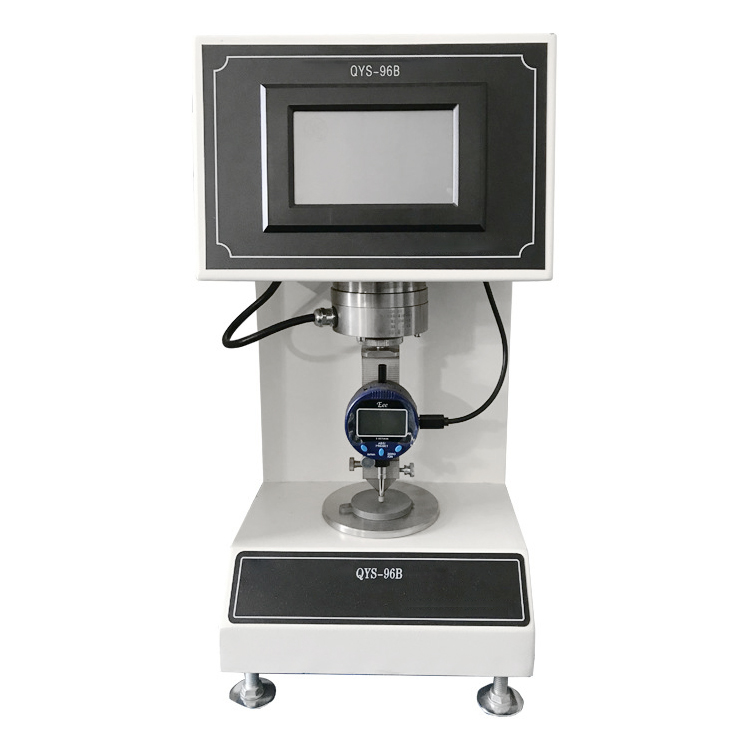

HST-QYS96 Plastic Ball Indentation Hardness Tester

1.Application scope

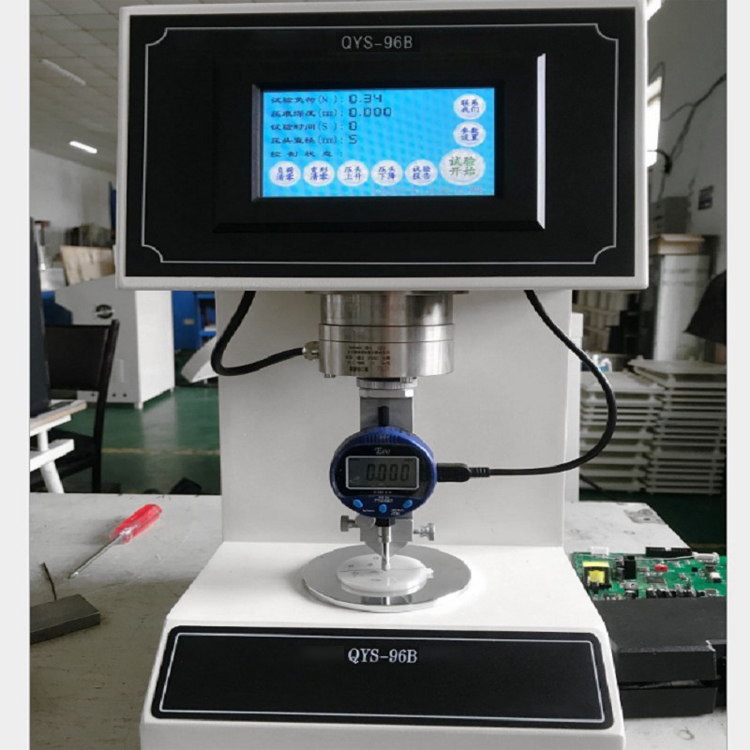

This instrument can be used to measure the hardness of materials in automotive engineering plastics, plastic building materials and other industries, and can process and print data. This machine adopts color touch screen technology to make the operation simpler, more intuitive and the picture more beautiful.

2.Standard:

Product manufacturing and inspection standards

1. JB/T7410-94 "Plastic Ball Indentation hardness tester Technical Conditions"

2. JJG 369-1993 "Plastic Ball Indentation Hardness Tester Verification Regulations"

Applicable test method standards

1. GB3398.1-2008 "Plastic Hardness Determination Part 1: Ball Indentation Method"

2. ISO2039-1: 2001 "Plastic Hardness Determination Part 1: Ball Indentation Method"

3.Main Specifications

1. The test load is divided into six levels: 9.8N (preload), 49N, 132N, 358N, 612N, 961N

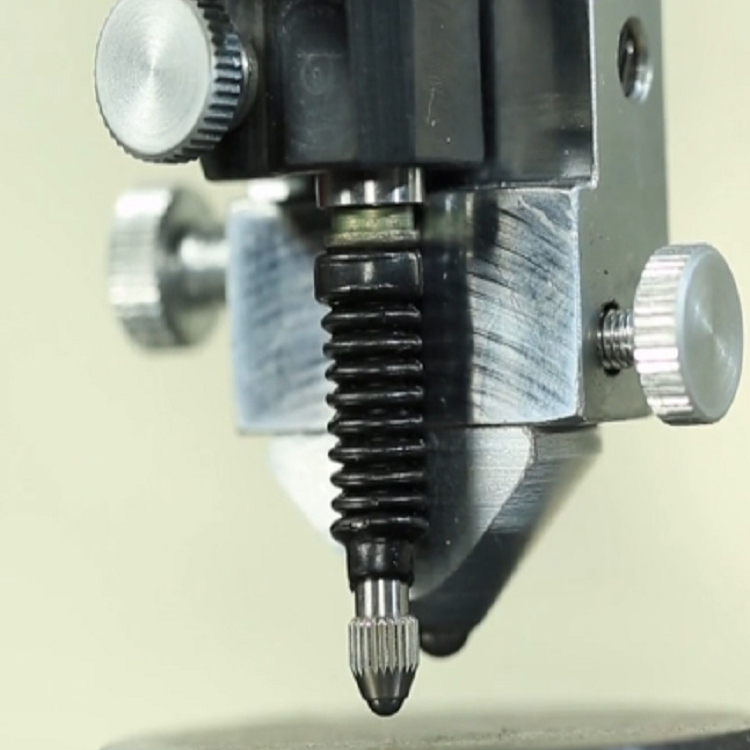

2. Steel ball indenter: Φ5mm, Φ10mm

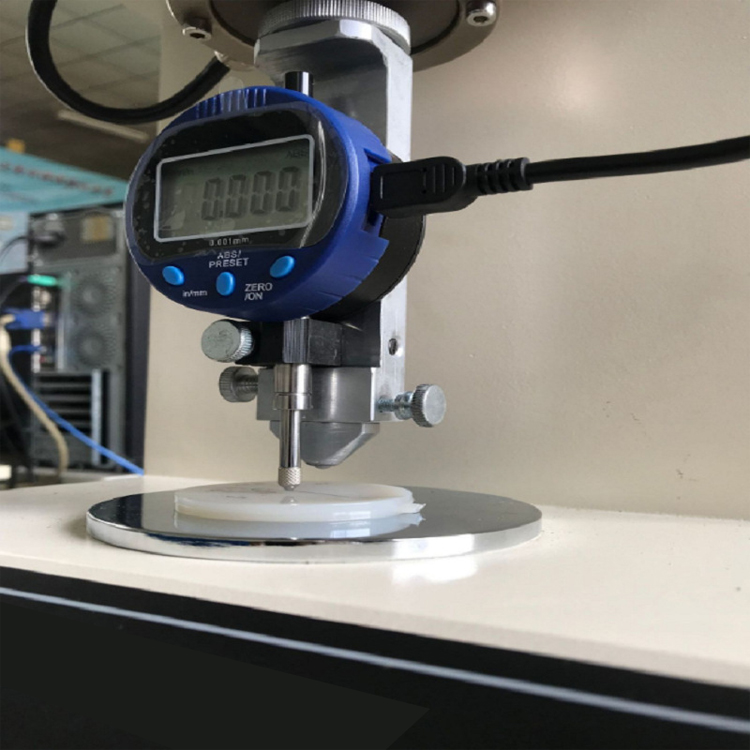

3. Minimum graduation value of indentation depth indication: 0.001mm

4. Maximum allowable height of specimen: 10mm

5. Distance from pressure head to machine wall: 55mm

6. Indication accuracy: ±4%

7. Timing range: 10~90s, timing accuracy ±0.1s

8. Effective measurement range: 0.150~0.350mm

9. Frame deformation: ≤0.05mm

10. Equipment weight: 45kg

11. Equipment dimensions (mm): 330×220×425

4.Configuration

|

Name |

Remark |

Qty |

Origin |

|

Host |

HST-QYS96 |

1 set |

HST |

|

High precision sensor |

LCD10KN |

1 |

Changchun |

|

Deformation sensor |

0-6.5mm |

1 |

Domestic |

|

Pressure head |

Φ5mm,Φ10mm |

1 each |

HST |

|

Base |

|

1 |

HST |

|

micro printer |

WH-E22 |

1 set |

Beijing Weihuang |

|

Deformation acquisition system |

|

1 set |

HST |

|

Loading control system |

|

1 set |

HST |

|

Data microprocessing system |

|

1 set |

HST |

|

Microcontroller software |

|

1 set |

HST |

![]()