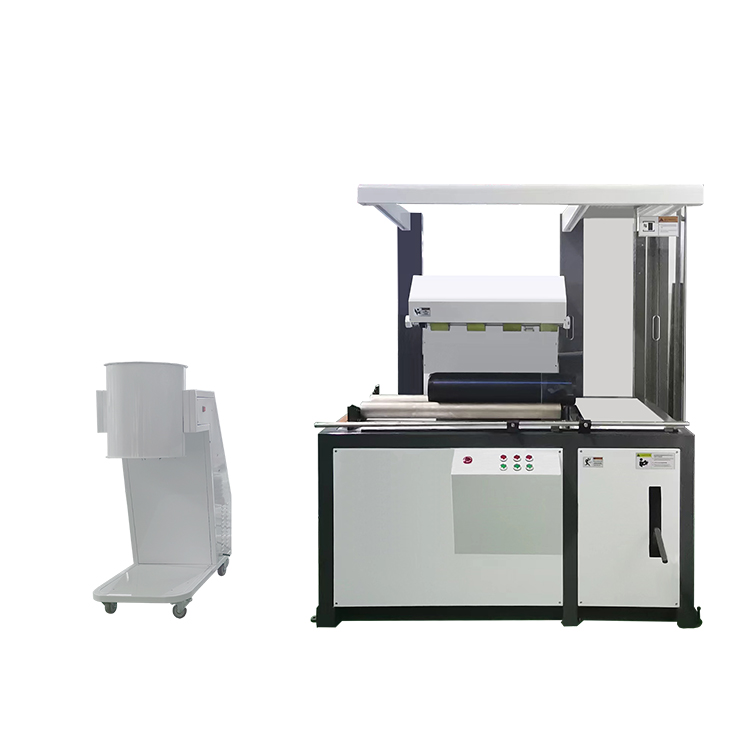

HST-PT Rubber plate Vulcanizing Press Testing Test Machine

HST-PT Rubber plate Vulcanizing Press Testing Test Machine

Standards:

Request A Quote Files DownloadApplicable Industry

It mainly used in producing vulcanizing parallel adhesive type, such as conveyor belt,driving belt, and pressing rubber products, foamed plastic,thermosetting plastic(bakelite) and other plastic products. It also suitable for O ring,the key products such as cell phone, keyboard,remote-control,sealing washer such as pressure cooker, electric cooker, mechanical accessories for household, food, health and medical treatment. At the same time,this machine alsocan be used in complex silicone and rubber fittings production and process, such as nipple,medical supplies, health product, artware, toy seal, electroconductive rubber, automotive rubber parts, industrial rubber parts,medical silicone product, sport equipment, all kinds of vessels, multilayer product and so on.

Features

1.Controlled by PC or manual, performance reliable, high degree of automation. Can automatically identify the wrong command,so avoid the accidence which caused by wrong operation.

2.The preprogrammed process can be locked, the operator can not change without authorization, so that guarantee the quality of pressed product.

3.With the function of timing open mold, automatically exhaust and reinforcing pressure, etc.

4.Optional: Manual operating or Automatic operating mode

5.Electrical heating pressing machine apply digital display(or pointed type) to control temperature, and control and display the heating plate temperature.

Technical Parameters

Capacity

20~50Ton optional

Temperature range

RT~300℃

Controller

Optional electrical control and PLC programmable control

Vulcanization time

0.1S~99M~9.9H

Heating methods

Electric heating module

Temperature accuracy

±2℃

Thermal pressure plate

300×300mm

Cooling presure plate

300×300mm

Plate distance

70mm

Pressure plate material

SKD Chromium molybdenum alloy

Pressure plate hardness

HRC50~60

Pressure plate surface

Mirror chrome plated

Pressure plate layer

double

water cooling system

Tap water cooling/compressor cooling water (optional)

water cooling temperature

+5℃

Exhaust times

0~3times

Hydraulic system

GPY oil pump drive high performance electro-hydraulic with no resistance cylinder execution speed control mode, can be preset one, two pressure and time.

Oil cylinder stroke

Max 200mm

Cylinder speed

11mm/s

Pressure force gauge

0~350kg/ cm2

Work rate

10.6HP

Size(W×D×H)

1000×500×1500 mm

Power

3PHASE,AC380V,20A

Weight

658kg