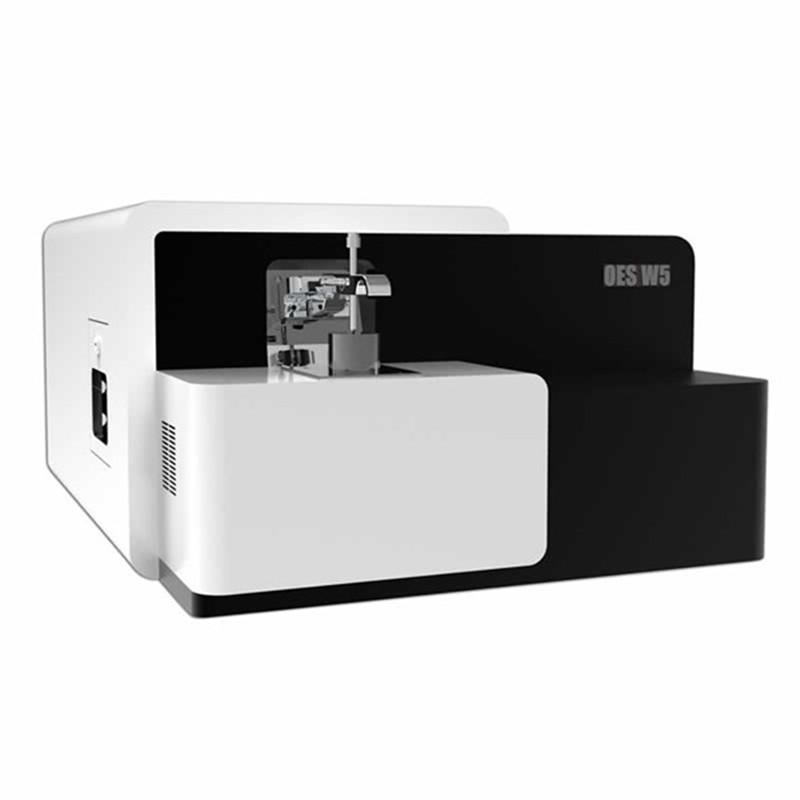

HST W6 Vacuum Arc Spark Optical Emission Spectrometer

Summary:

HST-W6 Optical Emission Spectrometer is the most advanced Arc/Spark-OES with Ultimate Performance for Metal Analysis. It uses full-digital technology to replace bulky photomultiplier tube (PMT) simulation technology and in the lead of international spectrometer technology. The adoption of vacuum optical chamber design, full-digital excitation light source, advanced CMOS detectors, and high-speed data readout system equips the device with high properties, ultra-low limit of detection (LOD), long-term stability and repeatability. Its analytical precision reaches the world leading level. It is one of the major devices that applies to quality control, material brand recognition, material research and development in the metallic manufacturing, processing and smelting industry. This analyzer sets a new standard for R&D and process/quality control.

Applications:

W6 optical emission spectrometers(spark OES) as one of the major devices that applies to quality control, material brand recognition, material research and development in the metallic manufacturing, processing and smelting industry.W6 are used for applications in metal elemental analysis, trace element analysis for science and industry like Metallurgy, Foundry, Mechanical Engineering, Scientific Research, Product Inspection, Automobile, Petrochemical Engineering, Shipbuilding, Electrics, Aerospace, Nuclear Power, Metallic and Nonferrous Metallic Smelting, Processing and Recycling.

High-end Laboratories Defence, Railways, pure research, etc.

Large Steel Plants Rapid analysis with limits in low to single-PPM range on C, S, P, B, N, Ti

Pure metal applications 99.95%+ purity Al, Pb, Zn, Cu etc.

Regulatory compliance Very low LODs to control Pb, Cd, As etc. (e.g. ship-making)

Specialty alloy makers: Wide range of elements with low detection limits

Manufacturing Facilities

Warehouse material identification

Base: Fe, Cu, Al, Ni, Co, Mg, Ti, Zn, Pb, Sn, Ag etc