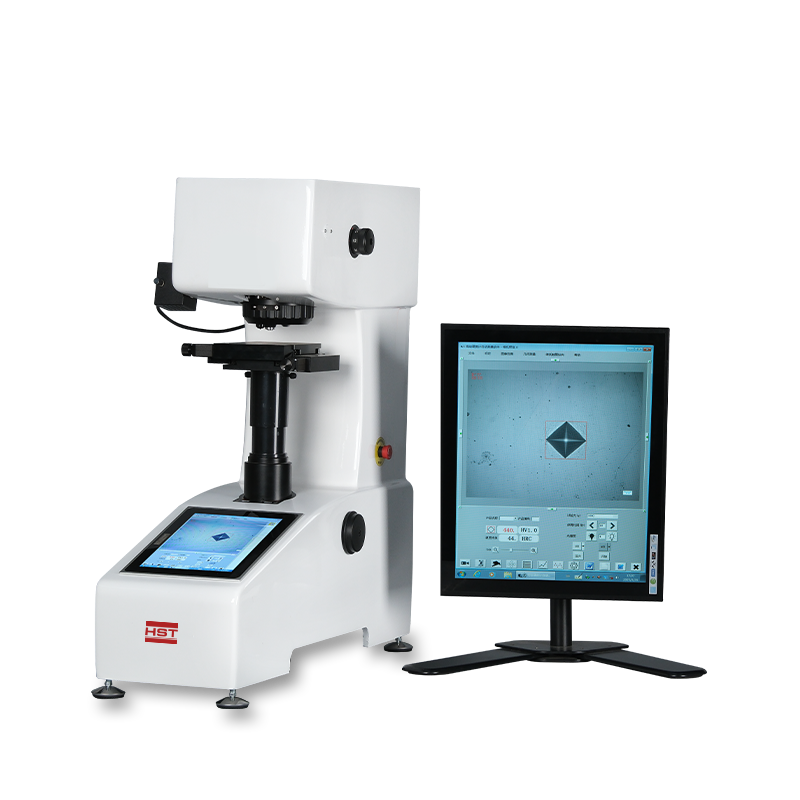

HRS 150/45DX-ZXY Fully Automatic Rockwell Hardness Tester

Application Fields:

Industrial production, Inspection of product quality on processing technology. Ferrous and nonferrous metals, Hardened steel, tempered steel, annealed steel, hardened steel, sheet of various thicknesses, carbide materials, powder metallurgy materials, hardness and thermal spray coating.

Sheet metal, thin-walled pipe, hardened steel, and small parts of hardness.

Widely used in machinery manufacturing, metallurgy plants, universities, laboratories, etc.

Main Technical Specifications:

Industrial production, Inspection of product quality on processing technology. Ferrous and nonferrous metals, Hardened steel, tempered steel, annealed steel, hardened steel, sheet of various thicknesses, carbide materials, powder metallurgy materials, hardness and thermal spray coating.

Sheet metal, thin-walled pipe, hardened steel, and small parts of hardness.

Widely used in machinery manufacturing, metallurgy plants, universities, laboratories, etc.

Main Technical Specifications:

| Conversion Scale | Rockwell ,Brinell,Vickers |

| Application | Applied for repeatedly testing large quantity of specimens |

|

Preload for Rockwell hardness |

98.1N (10kgf) |

|

Main Force for Rockwell hardness |

60kgf(588.4N)100kgf(980.7N)150kgf(1471N) |

| Force error | ≤0.5% |

| Preload for Superficial Rockwell hardness | 29.4N(3kgf) |

|

Main Force for Superficial Rockwell hardness |

15kgf(147.1N)30kgf(294.2N)45kgf(441.3N) |

| Superficial Rockwell test range |

HR15N:70-94 HR30N:42-86 HR45N:20-77 HR15T:67-93 HR30T:29-82 HR45T:10-72 |

| Dwelling Time | 0~60s |

| Rockwell Scales |

HRA:20-96 HRB:20-100 HRC:20-70 HRD:40-77 HRE:70-100 HRF:60-100 HR G 30-94HRH:80-100 HRK:40-100 HRL:50-115 HRM:50-115 HRR:50-115 |

| Carry Out Standard | Chinese Standard GB/T230.1, GB/T230.2, JJG112 Inspection Rule, ASTM Standard |

| Max Height of Specimen | 175mm, Added Height: 400mm |

| Distance between Indenter to outer wall | 160mm |

| Specimen Rising Speed | 3mm/s |

| Specimen Rising Up | Automatically |

| Apply Initial Test Force | Automatically |

| Apply Main Test Force | Automatically |

| Specimen moving in X or Y Axis | Automatically Move |

| Moving Precision in X or Y Axis | 0.003mm |

| Travels in X or Y Axis Direction | 100mm |

| Hardness Value Display | Automatically |

| Hardness Value Exchange | Automatically |

| Hardness Values Output | Built-in Printer, RS232 Interface, Normal Printer |

| Hardness Statistic and Analysis | With |

| Hardness Test Database Inquiry | With |

| User’s Stipulated Inspection Report | Automatically Form |

| Exchange Scales | Superficial Rockwell, Brinell, Vickers |

| Readout Hardness Value | Large Digital Display Screen |

| Overall Dimension (mm) | 520x240x720mm |

| Power Supply | AC220V |

| Net Weight of Main Tester | About 65kg |